Our Innovation and Technology

Breathable

Technology

Designed to be Professional

Structure Design Inspirations

- Professional shapewear requires continuous research and development iterations to continuously provide women with a better wearing experience.

- Based on ergonomics and construction mechanics, the stable shapingdesign is perfect to bring comfort and plasticity to women.

Made By Heart

Taking Care of Your Growth and Beauty

- Professional plastic clothing to accompany the growth of women, favored by consumers.

- Professional plastic clothing has professionalism in function, research and development, fabric, quality control, etc., and has a full voice in the market, forming wide influence on consumers and being recognized by them.

- Consumers need care and support from teenage girls, to entering the workplace, to becoming great mothers.

- S-SHAPER has a philosophy of designing different professional products for different women of different ages, shapes and styles, each of whom has an important life stage and their own unique beauty that cannot be simply described in one word.

- They have students, workplace beauty, teachers, doctors, nurses, and celebrities, regardless of occupation and age, they are among us.

S-SHAPER has its own factory. In the previous years, we have produced more than 1,000,000 pieces of shapewears to the world.

26 Processes

28 Fabric selections

40 Mold cup production processes

70 Cutting and sewing

30 Quality tests

The production of a piece of shapewear goes through26 processes, including 28 fabric selection and production processes,40 mold cup productionprocesses,70 cutting and sewing processes, morethan 30 quality inspection and testing processes, andphysical and chemical testing processes.

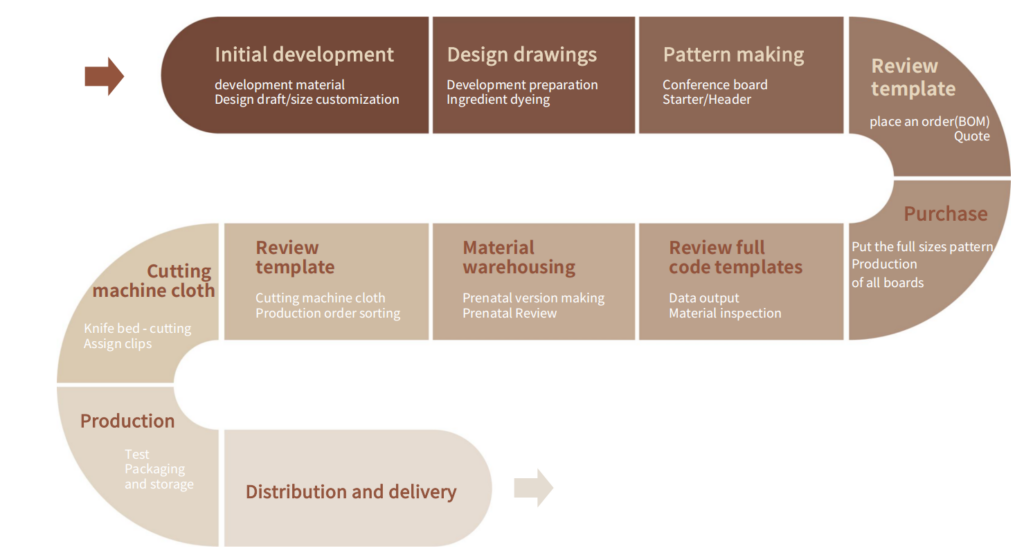

Product Production Procedure

We apply an evolutionary quality control standard to control the key production processes. The standard is reviewed half a year.

> Quality inspection determines the quality of lingerie, professional lingerie using sewing production process, the production process is complex, numerous processes, quality inspection throughout the production process. Strict quality inspection standards and processes to ensure the quality of professional lingerie production.

> Professional S-SHAPER shapewear factory, subject to corporate testing third-party national experiments underwear after washing the appearance of the effect of testing quality control, outdoor inspection, real people try on and other testing procedures, quality control standards are much higher than the industry.

> Simulation of customers in wearing after using a household drum washing machine on samples of 10 testing process higher tan national standards, including shrinkage, color fastness, formaldehyde, lie multiple washing, to seethe changes in appearance after washing Watch thing pH, piling, breathability, etc.; which, a single product internal control test items more than 40.

> The test items include 600 times repeated hooking test 10, 1000 times stretching test, 14400 times pilling test, etc. Whether the material is broken, deformed, shrunken, twisted, warped, uneven edge, hooking, yarn removal, pilling, etc. after washing.

> In addition to conventional testing, Urban Beauty also cooperates with national laboratories to add additional times after washing Temperature:30 degrees, washing time: about 1 hour/time.

> Appearance quality piling, air permeability, stretch elasticity, splicing inter-dyeing and other quality inspection items above the industry standard.

> S-SHAPER standard requirement:no holes after washing no loss of buttons and decorative accessories, no obvious deformation of the product, discoloration not less than 4 grade products. Before going on the shelves it will also be tied on by at least 100 real people for 1 month, and generally needs to be adjusted and optimized after 3 National Standard Requirement:No Requirement dozen rounds repeatedly, before the final confirmed version will be put into production.

Discover the Comfort and Elegance of S-SHAPER Shapewear

Join the S-SHAPER family today for exclusive access to the latest styles, special offers, and a world where fashion meets function!

Contact Us

- +86 18129831782

- [email protected]

- Rm2406, Qianhai HOP International Building, Baoan Center, Shenzhen, China 518133

© S-shaper All Rights Reserved 2025

Powered by Easyceotech