OEM Laser Cutting Panties Manufacturer for Premium Lingerie

1. Introduction to OEM Laser Cutting Panties in the Premium Lingerie Market

In the evolving landscape of premium lingerie, one innovation stands out for its seamless aesthetics and high-end appeal—laser cutting technology. Laser cutting panties have become a go-to solution for lingerie brands looking to deliver elevated comfort, invisible lines, and a streamlined silhouette to fashion-conscious consumers. For B2B buyers, including wholesale lingerie distributors, boutique retailers, and private label startups, sourcing from an experienced OEM laser cutting panties manufacturer is crucial for brand success.

Laser cutting refers to the use of high-precision laser technology to create clean, sealed edges in fabrics—eliminating the need for traditional stitching or hems. This technique is especially advantageous in the lingerie industry, where comfort, fit, and minimal visibility under clothing are paramount.

For premium lingerie brands, investing in OEM services for laser-cut panties allows for complete customization in terms of design, fabric, sizing, and branding. Furthermore, it enables faster go-to-market timelines, reduced manufacturing defects, and a consistent, luxury-grade finish that meets the expectations of high-end consumers.

Why Laser Cutting Panties Are Gaining Popularity

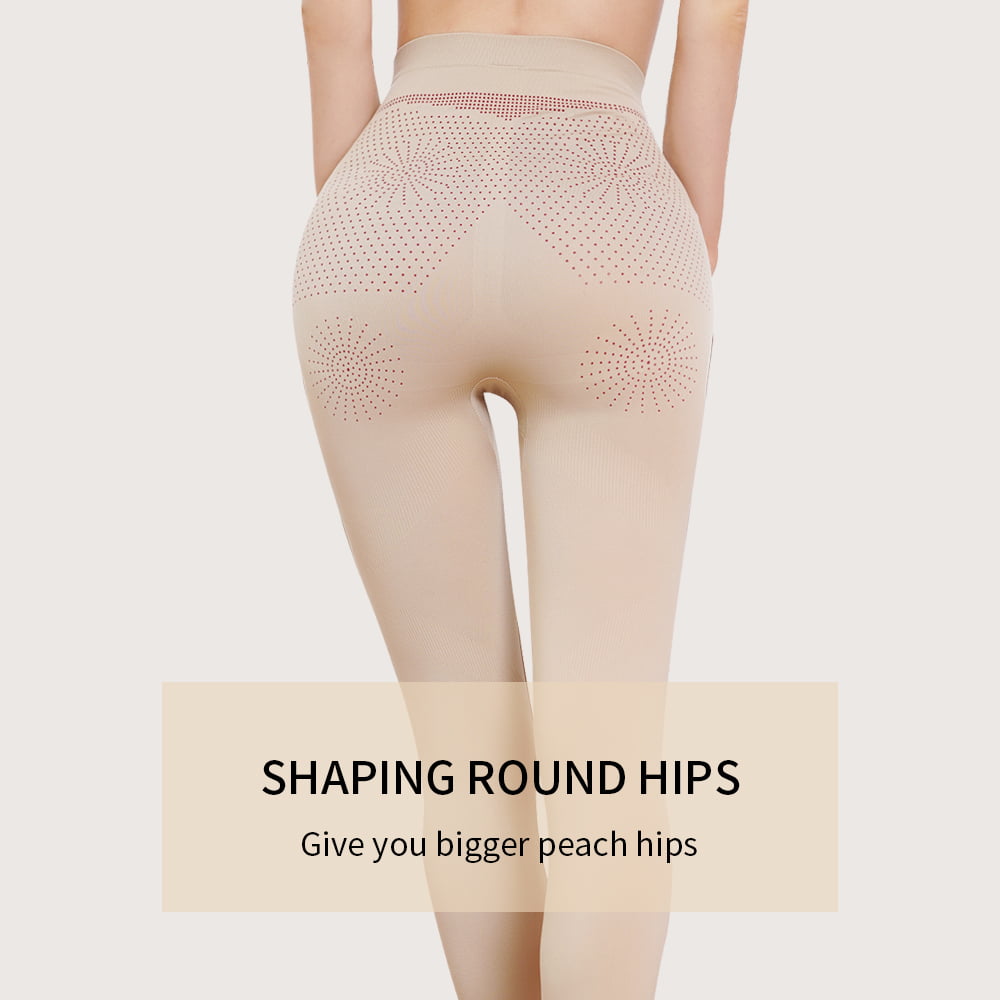

- ✅ Seamless edges for invisible wear under tight clothing

- ✅ No fraying or unraveling due to sealed hems

- ✅ Sleek, minimalist design perfect for modern lingerie collections

- ✅ Lightweight and breathable—ideal for comfort-focused consumers

- ✅ Customizable for different levels of compression and shaping

Applications in the Lingerie Industry

| Application | Description |

|---|---|

| Everyday Lingerie | Perfect for invisible wear under yoga pants, jeans, or skirts |

| Luxury Collections | Adds a modern flair to minimalist or high-fashion lingerie lines |

| Post-Surgery Wear | Seamless edges reduce irritation and friction |

| Activewear Add-ons | Pairs well with athleisure and activewear-focused lingerie lines |

2. How to Choose the Best Laser Cutting Panties Manufacturer for Your Private Label

Choosing the right OEM lingerie manufacturer is a strategic decision that impacts your brand’s quality, delivery times, and customer satisfaction. The ideal partner should offer not only advanced laser cutting capabilities but also flexible production options, regulatory compliance, and a proven track record in premium lingerie manufacturing.

For businesses looking to launch or scale their lingerie line with laser-cut panties, here are the key factors to consider:

Key Criteria for Selecting a Reliable OEM Manufacturer

| Criteria | Why It Matters |

|---|---|

| Laser Cutting Technology | Ensure the manufacturer uses precision CO2 or fiber laser cutters |

| Fabric Compatibility | Ability to work with microfiber, nylon, modal, spandex blends |

| OEM/ODM Support | From design development to private labeling and packaging |

| Production Scalability | Can handle small MOQ to high-volume orders |

| Customization Options | Sizes, colors, compression levels, and branding |

| Certifications | ISO, OEKO-TEX®, BSCI, and other compliance standards |

| Lead Time & Logistics | Efficient sample development and global shipping capabilities |

What to Ask Potential Suppliers

- Do you offer rapid prototyping for laser-cut panty designs?

- What is your minimum order quantity (MOQ) for private label?

- Can you assist with fabric recommendations for seamless underwear?

- Do you offer custom packaging and logo branding?

- How do you ensure consistent quality in laser-cut products?

Benefits of Partnering with S-SHAPER for Laser Cut Panties

When it comes to sourcing premium-quality laser cutting panties from China, S-SHAPER stands as a trusted OEM lingerie manufacturer with advanced technical capabilities and global service standards. Here’s why S-SHAPER is the preferred partner for lingerie brands worldwide:

- ✅ In-house R&D team for custom design and prototyping

- ✅ 48-hour sample development for rapid testing and market entry

- ✅ Small-batch MOQ starting at 50 pieces—ideal for startups

- ✅ Global warehouses and flexible logistics for timely delivery

- ✅ Advanced laser cutting and seamless knitting techniques

As a leading shapewear and lingerie OEM/ODM manufacturer, S-SHAPER empowers brands with full-spectrum services—from concept to mass production—delivering not just products but strategic growth.

3. Advantages of OEM vs. ODM for Laser Cut Panty Production in Premium Lingerie

When sourcing from an overseas lingerie manufacturer, one of the first decisions B2B buyers must make is whether to go for an OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) model. Both approaches have their merits, but your choice should align with your brand’s development stage, design capabilities, and market goals.

Difference Between OEM and ODM in Lingerie Manufacturing

| Model | Description | Best For |

|---|---|---|

| OEM | You bring your own designs, and the manufacturer produces them to spec | Established brands or those with in-house designers |

| ODM | The manufacturer provides design concepts, and you select or customize from existing templates | Startups or brands needing creative and technical support |

OEM Benefits for Premium Lingerie Brands

- Full control over design, fit, and materials

- Ideal for unique brand positioning and exclusivity

- Allows for better IP protection and brand identity

- Custom packaging and labeling options

ODM Benefits for B2B Buyers

- Access to ready-made designs with proven performance

- Faster time to market with lower R&D investment

- Lower development costs, especially for small businesses

- Expert guidance on fabric, fit, and trend alignment

Why S-SHAPER Offers the Best of Both Worlds

At S-SHAPER, brands don’t have to choose between OEM and ODM. Our hybrid flexibility allows you to start with ODM and graduate to OEM as your brand evolves.

| S-SHAPER Services | OEM | ODM |

|---|---|---|

| Custom Fabric Selection | ✅ | ✅ |

| Private Label Branding | ✅ | ✅ |

| In-House Design Team | ❌ | ✅ |

| Prototyping & Sampling | ✅ | ✅ |

| Mass Production | ✅ | ✅ |

Whether you need full creative control or expert design assistance, S-SHAPER’s OEM/ODM services are tailored to meet the unique demands of premium lingerie brands.

We also offer direct access to our state-of-the-art factory, ensuring transparency, quality assurance, and scalability—critical for long-term B2B partnerships.

4. Top 10 OEM Laser Cutting Panties Manufacturers for Wholesale & Private Label

For lingerie brands and B2B buyers seeking high-quality laser-cut panties, choosing the right manufacturer is crucial. Here’s a curated list of the top 10 OEM manufacturers globally—ranked for their product quality, customization capabilities, and B2B-friendly services.

🏆 Top 10 Laser Cutting Panties Manufacturers (Global)

| Rank | Manufacturer | Country | Key Features | MOQ | OEM/ODM Support |

|---|---|---|---|---|---|

| 1 | S-SHAPER | China | Laser cutting, seamless knitting, shapewear expertise, low MOQ | 50 pcs | ✅ OEM & ODM |

| 2 | Chantelle Group | France | Luxury lingerie, eco-friendly materials, innovation-driven | Depends on project | ✅ OEM |

| 3 | Lauma Fabrics | Latvia | High-tech European production, intimate wear specialist | Moderate | ✅ OEM |

| 4 | Wolford AG | Austria | Premium seamless lingerie, laser-cut microfiber | High | ✅ OEM |

| 5 | Delta Galil | Israel | Full-package solutions, global supply chain | Custom | ✅ OEM/ODM |

| 6 | Tefron | Israel | Circular knitting and seamless underwear | 1,000+ | ✅ OEM |

| 7 | Yintai Garments | Vietnam | Experienced in Western markets, laser cut panties | 300+ | ✅ OEM |

| 8 | Hop Lun | Hong Kong | Mass production, supply to global lingerie brands | 500+ | ✅ OEM/ODM |

| 9 | Embry Form | China | Domestic giant in lingerie, laser and seamless tech | 1,000+ | ✅ OEM |

| 10 | MAS Holdings | Sri Lanka | Premier lingerie manufacturer, sustainable focus | 1,000+ | ✅ OEM/ODM |

Why S-SHAPER Stands Out as a Chinese Manufacturer

S-SHAPER is the only China-based factory on this list recommended for its unbeatable blend of:

- 🔧 Precision laser cutting with seamless design

- 🔁 Rapid prototyping within 48 hours

- ⚙️ Flexible order sizes: from 50 to 1M+ pieces/month

- 🌍 Global shipping with 8+ international warehouses

- 🧵 Customization of fabrics, compression levels, and packaging

For premium lingerie brands that want scalable manufacturing with design flexibility, S-SHAPER delivers reliability, speed, and innovation above industry standards.

5. How Custom Laser Cut Panties Can Strengthen Your Lingerie Brand Identity

In the highly competitive world of intimate apparel, differentiation is key. Custom laser-cut panties allow brands to stand out through innovative design, superior comfort, and a unique branding experience that resonates with modern consumers.

Key Branding Opportunities with Custom Laser Cut Panties

| Feature | Branding Value |

|---|---|

| Fabric & Finish | Choose from recycled microfibers, modal, or nylon for eco-conscious branding |

| Cut & Fit | Tailor to your target market’s size and comfort preferences |

| Seamless Design | Communicates minimalism and luxury |

| Logo Placement | Laser-etched tags or heat transfer logos within waistband |

| Packaging | Eco-friendly, branded boxes or premium silk pouches |

Design Elements That Enhance Brand Identity

- 🎨 Color Palette: Create seasonal or signature hues

- 🧵 Stitch-Free Edges: Communicate modern, innovative design

- 🧷 Compression Variants: Offer shaping or comfort variants under the same style

- 🧼 Skin-Safe Materials: Align with clean beauty and wellness trends

Case Study: Boutique Lingerie Brand Using S-SHAPER

A European boutique brand partnered with S-SHAPER to launch a minimalist lingerie line using laser-cut panties. Key results:

- ⚡ 30% faster development with S-SHAPER’s rapid prototyping

- 📈 45% increase in repeat purchases due to comfort and invisible wear

- 🌿 Brand positioned as eco-luxury with OEKO-TEX® certified fabrics

With support from S-SHAPER’s OEM/ODM services, the brand successfully scaled from 500 units to 10,000+ monthly orders in under a year—proving the power of custom design and reliable production.

6. Sourcing Laser Cut Panties from China: What B2B Buyers Should Know

China remains a global hub for lingerie and shapewear manufacturing, offering advanced textile technology, skilled labor, and cost-effective production. However, not all factories are equipped with the laser cutting machinery and quality control processes needed for premium lingerie.

Key Advantages of Sourcing from China

- 🏭 Advanced manufacturing infrastructure with high-volume capacity

- 💡 Access to cutting-edge technologies like seamless knitting and laser cutting

- 💰 Competitive pricing for OEM/ODM services

- 🚢 Efficient logistics and global shipping networks

- 📈 Scalability for growing brands and high-volume retailers

What to Look for in a Chinese Laser Cutting Panty Manufacturer

| Feature | Why It Matters |

|---|---|

| In-House Machinery | Ensures precision and consistency |

| Sample Development | Speed and accuracy in prototyping |

| Certifications | ISO, BSCI, OEKO-TEX® for global compliance |

| Transparent Communication | Smooth B2B negotiations and project management |

| Low MOQ | Ideal for SMEs and boutique brands |

The S-SHAPER Advantage

As a leader in China’s premium shapewear and lingerie sector, S-SHAPER offers unmatched value for B2B buyers:

- In-house laser cutting and seamless knitting equipment

- Low MOQ starting at just 50 pieces

- 48-hour sample turnaround with full customization

- Global warehousing and fulfillment support

- Dedicated OEM/ODM project managers

And with a direct factory view, buyers gain confidence in the production process—critical for building long-term partnerships.

7. Shapewear Factory vs. Trading Company: What’s Better for B2B Buyers?

When sourcing laser-cut panties or any premium lingerie products for your brand, one major decision is whether to work directly with a shapewear factory or go through a trading company. This choice affects your control over the product, cost, lead times, and overall business scalability.

Understanding the differences between these two sourcing models is crucial for wholesalers, private label brands, and distributors aiming to optimize their supply chain and profitability.

Factory vs. Trading Company: A Comparison Table

| Feature | Shapewear Factory (e.g., S-SHAPER) | Trading Company |

|---|---|---|

| Product Control | Direct communication with production team | Indirect; relies on third-party factories |

| Customization Flexibility | High – full OEM/ODM options | Limited by factory’s capabilities |

| Cost Efficiency | Lower unit costs, no middlemen | Higher due to markups |

| Production Transparency | Full visibility of production process | Limited visibility |

| Lead Time | Faster – direct sample & bulk production | Slower due to coordination delays |

| MOQ (Minimum Order Quantity) | More flexible – e.g., 50 pcs at S-SHAPER | Often higher |

| Quality Assurance | In-factory QC systems | Varies depending on third-party QC |

| Scalability | Easier to scale production | Depends on factory partnerships |

| Relationship Building | Long-term strategic partnerships | Transactional and less consistent |

Why Working with a Factory is Better for Premium Lingerie Brands

- 🔧 Direct access to R&D teams for custom designs

- 📉 Reduced costs and faster turnaround

- 🧵 Better alignment on materials, fit, and brand vision

- 🛠️ Easier problem-solving and faster revisions

S-SHAPER: Your Direct Factory Partner

Unlike trading companies, S-SHAPER is a fully integrated shapewear and lingerie factory offering:

- End-to-end OEM/ODM services

- Rapid design, sampling, and production cycles

- Transparent pricing and production timelines

- In-house quality control and advanced laser cutting machines

By working directly with S-SHAPER, B2B buyers eliminate unnecessary intermediaries, reduce costs, and gain full control over their lingerie brand’s production—ensuring consistency, scalability, and long-term success.

8. Contacting a Laser Cutting Panties Manufacturer: What to Prepare & Expect

Once you’ve identified a qualified OEM manufacturer like S-SHAPER, the next step is to initiate communication and begin the product development process. Being prepared with the right information will help streamline the conversation and lead to a smoother experience.

What to Prepare Before Contacting the Manufacturer

| Item | Description |

|---|---|

| Product Specifications | Style reference, desired cuts, fabrics, sizing, compression, etc. |

| Tech Packs or Sketches | Visuals that help communicate your design ideas |

| Brand Guidelines | Logo, colors, tone, packaging preferences |

| Target Market | Helps the manufacturer suggest suitable materials or features |

| Order Volume | Initial and projected quantities for MOQ discussion |

| Timeline | Expected launch date or important milestones |

Typical Questions a Manufacturer Will Ask You

- What fabric do you prefer for the laser-cut panties? Nylon, modal, or microfiber?

- Do you have a reference sample or tech pack?

- What level of compression or stretch are you targeting?

- Do you require seamless knitting in addition to laser cutting?

- What’s your expected monthly order volume?

What to Expect from S-SHAPER During the Process

At S-SHAPER, the communication process is streamlined for efficiency:

- Initial Consultation – Discuss your brand, needs, and product ideas.

- Design & Sampling – Our in-house design team prepares samples based on your brief.

- Quotation & Timeline – Get a detailed quote based on volume, materials, and packaging.

- Production Launch – Once the sample is approved, bulk production begins.

- Quality Control & Shipping – Every piece is inspected, packed, and delivered globally.

S-SHAPER also provides multilingual support to cater to international clients and maintains 8+ global warehouses for efficient logistics and cost-effective delivery.

9. Frequently Asked Questions (FAQ)

Q1: What’s the minimum order quantity (MOQ) for laser-cut panties at S-SHAPER?

A: At S-SHAPER, the MOQ starts as low as 50 pieces—ideal for startups and boutique brands. We also support scaling your order volume as your brand grows.

Q2: Can I customize the fabric, color, and fit of the panties?

A: Yes. We offer full OEM customization including fabric selection (nylon, modal, microfiber), color matching, sizing, compression level, and seamless design.

Q3: How long does it take to receive samples?

A: We offer rapid prototyping services, with samples ready in as fast as 48 hours. This reduces your development timeline and helps you test products faster.

Q4: Do you offer private label or branded packaging?

A: Absolutely. Our OEM services include logo placement, custom packaging, hang tags, labels, and even eco-friendly packaging options to match your brand identity.

Q5: Are your materials and production processes certified?

A: Yes. Our materials meet OEKO-TEX® standards and our factory adheres to ISO and BSCI compliance protocols. We ensure all products are safe, comfortable, and high-quality.

Q6: How do I get started with S-SHAPER?

A: Simply contact us through our website with your product idea or brand requirements. Our team will guide you through every step—from design to delivery.

By choosing S-SHAPER as your OEM laser cutting panties manufacturer, you gain a strategic partner dedicated to premium quality, seamless innovation, and business scalability. Whether you’re launching a new lingerie line or expanding an existing one, S-SHAPER provides the tools, expertise, and infrastructure to turn your ideas into best-selling products.

🌐 Explore our OEM/ODM services, browse our product offerings, or learn more about our factory capabilities. Ready to bring your lingerie brand to life? Contact S-SHAPER today and take the first step toward seamless success.

Share This Post:

Related Posts

Custom backless shapewear slip dress solutions for Spanish bridal boutiques

Custom backless shapewear slip dress solutions for Spanish bridal boutiques are no longer a niche add-on; they are becoming a core profit and service differentiator. Spanish brides increasingly choose gowns

Custom color backless shapewear slip dresses for German wedding dress retailers

German bridal retailers looking to improve gown fit, reduce alterations, and increase accessory attach rates should prioritize custom color backless shapewear slip dresses as a core part of their assortment

Custom color backless shapewear slip dresses for the French bridal market

For French bridal brands and boutiques, the fastest way to elevate customer satisfaction and increase dress conversion is to secure custom color backless shapewear slip dresses for the French bridal

Custom Color and Fabric Backless Shapewear Slip Dress Lines for Japan Boutiques

Custom color and fabric backless shapewear slip dress lines for Japan boutiques succeed when brands prioritize precision, subtle aesthetics, and stable OEM execution from the start. For Japanese boutiques, the