Camisole Factory for Fashion Chains: How to Choose the Right Manufacturer for Bulk Orders

1. Why Fashion Chains are Investing in Private Label Camisoles

In today’s competitive fashion landscape, camisoles are no longer just undergarments—they are versatile essentials that appeal to a broad demographic. Fashion chains are increasingly investing in private label camisoles to:

- Gain full control over branding and design

- Improve profit margins by cutting out middlemen

- Respond faster to market trends with exclusive styles

- Build customer loyalty through consistent fit and quality

This surge in demand has given rise to a new wave of camisole factories ready to provide OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services tailored for fashion chains.

Market Trends Driving Camisole Demand

| Trend | Description |

|---|---|

| Athleisure & Comfort Wear | Camisoles are now worn as outerwear, driving up demand for stylish designs |

| Layering Essentials | Retailers need camisoles in multiple colors and fabrics for layering |

| Size Inclusivity | Fashion chains are expanding size ranges, requiring custom manufacturing |

| Eco-Conscious Buyers | Sustainable materials like bamboo or organic cotton are gaining traction |

Why Private Label Camisoles Make Business Sense

- ✅ Custom branding = stronger brand identity

- ✅ Higher margins vs. reselling branded products

- ✅ Ability to align product with target demographic

- ✅ Direct control over quality and supply chain

What This Means for Fashion Chains

For fashion retailers, camisoles represent a low-risk, high-velocity product. They are affordable to produce, have high sell-through rates, and fit well into both online and brick-and-mortar strategies. Choosing the right camisole factory is critical to scaling this product category successfully.

2. Key Features to Look for in a Camisole Factory

Selecting the right camisole manufacturer is pivotal for fashion chains aiming to scale efficiently. Whether you’re sourcing for a fast-fashion brand or a premium boutique chain, the factory you choose must meet specific criteria.

Essential Criteria for Choosing a Camisole Factory

| Feature | Why It Matters |

|---|---|

| OEM/ODM Capabilities | Flexibility to either manufacture your designs or develop new ones |

| Fabric Technology | Access to performance fabrics, seamless designs, and eco-materials |

| MOQ Flexibility | Ability to support both small test runs & large-scale production |

| Lead Time Efficiency | Shorter production cycles for fast-fashion agility |

| Custom Packaging & Branding | Enhances shelf appeal and brand consistency |

| Size Range & Inclusivity | Accommodates broader customer demographics |

| Certifications & Compliance | Ensures ethical practices and quality assurance |

Questions to Ask When Vetting a Camisole Factory

- Do you offer both OEM and ODM services?

- What is your monthly production capacity?

- Can you provide samples in different fabrics (modal, cotton, bamboo)?

- Do you have in-house design and prototyping?

- What are your quality control processes?

- Are you experienced in working with fashion chains?

Red Flags to Avoid

- Factories that outsource most of their production

- No clear documentation of quality control or certifications

- Inflexible MOQs that may not suit your current scale

- Poor communication or delayed sample turnaround

3. S-SHAPER: The Leading Camisole Manufacturer in China

When it comes to sourcing high-quality camisoles from China, one name stands out above the rest — S-SHAPER. As a global leader in shapewear, bodysuits, and intimate apparel, S-SHAPER has emerged as a trusted camisole factory for fashion chains across Europe, North America, and Asia.

Why S-SHAPER is the Go-To Camisole Factory for Fashion Chains

| Feature | S-SHAPER Advantage |

|---|---|

| OEM & ODM Expertise | Full-service solutions from concept to delivery |

| Rapid Prototyping | 48-hour sample development to reduce time-to-market |

| Low MOQs Starting at 50 Pieces | Perfect for test launches and capsule collections |

| Scalable Production | Capable of producing up to 1 million pieces/month |

| Global Logistics Support | 8+ international warehouses for fast and cost-effective delivery |

| Advanced Fabric Technology | Moisture-wicking, seamless knitting, compression control |

| Custom Branding Services | Labels, packaging, hangtags, and more tailored to your brand |

S-SHAPER’s OEM & ODM Services

- 🧵 OEM: Bring your design, and S-SHAPER handles the rest—from sourcing to QC

- ✂️ ODM: Let S-SHAPER’s in-house design team develop exclusive camisole styles

🔗 Learn more about S-SHAPER’s full-spectrum services on their OEM/ODM Service Page

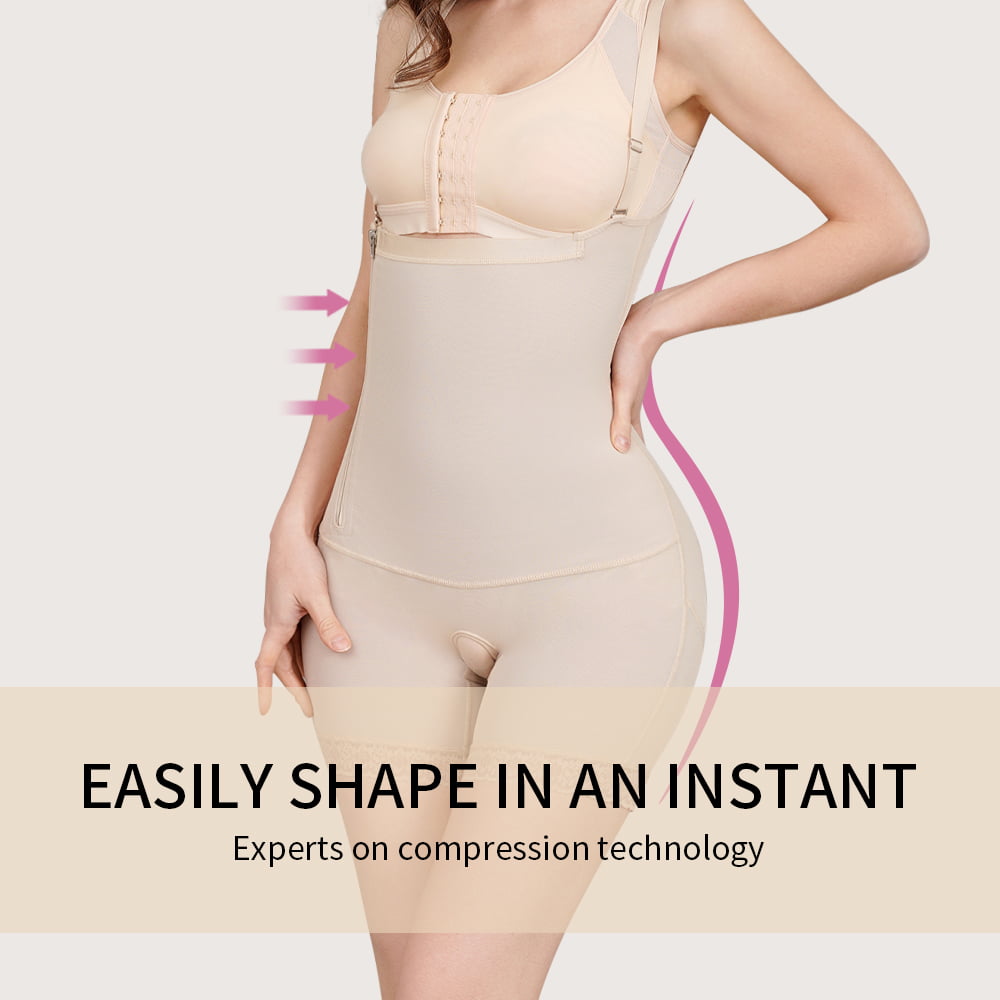

Camisole Types Offered by S-SHAPER

- Basic daily wear camisoles

- Lace-trimmed fashion camisoles

- Seamless camisoles for layering

- Compression camisoles for shaping

- Maternity and postpartum camisoles

Real-World Success: Retail Chain Collaboration

One European fashion chain partnered with S-SHAPER to develop an exclusive line of bamboo camisoles. Within 3 months, the product became a top-seller, thanks to:

- Fast sample turnaround

- Custom sizing from XS to 4XL

- Environmentally friendly materials

- Branded packaging with recycled paper tags

🔗 Explore their product range here to see what styles and innovations they offer.

4. Comparing OEM vs. ODM Camisole Manufacturing for Retail Chains

When sourcing camisoles for your fashion chain, understanding the differences between OEM and ODM manufacturing can determine the speed, flexibility, and uniqueness of your product launch. Both models offer distinct advantages depending on your brand’s needs, budget, and time-to-market goals.

OEM (Original Equipment Manufacturing) – Best for Established Brands

In OEM manufacturing, you provide the designs, specifications, and branding. The factory handles production based on your exact guidelines.

Pros of OEM Camisole Manufacturing:

- Full control over design, fit, and fabric

- Ideal for maintaining brand consistency across multiple product lines

- Custom patterns, trims, and packaging

- Better IP protection (especially for patented designs)

Cons:

- Requires in-house design resources

- Longer lead times for first samples

- Higher setup costs for tech packs and prototyping

ODM (Original Design Manufacturing) – Ideal for Fast-Moving Fashion Chains

ODM allows you to select from pre-designed camisole styles offered by the factory, which can be customized with your branding and minor modifications.

Pros of ODM Camisole Manufacturing:

- Faster time to market (styles are ready to go)

- Lower development costs

- Great for testing new product categories

- In-house R&D and trend forecasting by the manufacturer

Cons:

- Limited to available designs

- Less product differentiation

- Potential overlap with other brands using the same base styles

Comparison Table: OEM vs. ODM for Camisoles

| Feature | OEM Model | ODM Model |

|---|---|---|

| Design Ownership | 100% yours | Shared or modified factory designs |

| Time to Market | Longer (4–8 weeks) | Shorter (2–3 weeks) |

| Customization | Full (fabric, cut, size, packaging) | Partial (branding, fabric tweaks) |

| Cost | Higher initial cost | Cost-effective for smaller collections |

| Best For | Established brands | New brands or trend testing |

S-SHAPER offers both models, allowing fashion chains to start with ODM and later transition to OEM as they scale. This hybrid approach is ideal for brands that want to test demand before investing heavily in design infrastructure.

🔗 Discover more about these services on S-SHAPER’s OEM/ODM page

5. How to Evaluate Camisole Quality When Sourcing in Bulk

For fashion chains, poor quality control can translate into costly returns, negative reviews, and lost brand credibility. Whether you source from an overseas camisole factory or a local manufacturer, you must implement strict quality evaluation at every stage.

Key Quality Metrics for Camisoles

| Quality Factor | What to Check |

|---|---|

| Fabric Composition | Is it breathable, anti-pilling, and colorfast? |

| Stitching | Even seams, no loose threads, secure hemming |

| Fit & Sizing | Consistent across batches and sizes |

| Color Consistency | Shades should match across pieces and reorders |

| Stretch & Recovery | Fabric should retain shape after multiple washes |

| Labeling & Packaging | Branded correctly, no misprints, clean finishing |

Quality Control Tips for Large Orders

- ✅ Request Pre-Production Samples (PPS)

- ✅ Conduct Third-Party Quality Inspections

- ✅ Use a Standardized Fit Model for Testing

- ✅ Define Tolerance Levels in Tech Packs

- ✅ Include Wash Test Protocols in QC Checklist

Example Quality Control Checklist

| Item | Pass/Fail Criteria |

|---|---|

| Fabric Stretch | Min. 20% stretch; returns to original shape in 3 sec |

| Color Fastness | Score ≥ 4 after 3 washes |

| Size Tolerance | +/- 1cm deviation from spec allowed |

| Stitch Density | Min. 10 SPI (stitches per inch) |

| Packaging | Label aligned, no glue stains, polybag sealed |

At S-SHAPER’s factory, each camisole undergoes rigorous QC protocols, ensuring consistency in every batch. Their quality assurance includes fabric testing, fit trials, and visual inspections at key production stages.

6. Global Camisole Manufacturers: Best Suppliers in Turkey, Vietnam & Colombia

While China remains a dominant force in camisole manufacturing, global fashion chains are also exploring options in other countries for diversification, tariff navigation, and sourcing flexibility. Below are some of the most reputable camisole factories outside China.

Top Camisole Factories in Turkey

Turkey is known for its high-quality textiles, proximity to Europe, and fast turnaround times.

| Manufacturer | Key Strengths |

|---|---|

| Texmode Istanbul | Organic cotton camisoles, GOTS certified |

| Beks Camisoles | Premium trims and lacework for fashion-forward styles |

| Moda Tekstil | Quick sampling and low MOQs |

Leading Vietnamese Camisole Suppliers

Vietnam has gained popularity due to its cost efficiency and trade agreements with the EU and US.

| Manufacturer | Key Strengths |

|---|---|

| Vinatex Apparel | Large-scale production for global chains |

| TNG Investment & Trading | High compliance standards, BSCI certified |

| Dony Garment Co. | Specializes in seamless and sportswear camisoles |

Colombian Camisole Factories

Colombia is emerging as a high-quality manufacturing hub, especially for intimate wear and shapewear.

| Manufacturer | Key Strengths |

|---|---|

| Leonisa | Fashion-forward camisoles with control features |

| Intima Hogar | Postpartum and functional camisoles |

| Inconmoda Medellin | Trend-driven designs for Latin and U.S. markets |

While these countries offer strong alternatives, only China-based S-SHAPER combines innovation, scale, and flexibility under one roof—making it the top choice for fashion chains that prioritize quality and speed-to-market.

🔗 Ready to connect with a trusted factory? Visit S-SHAPER’s contact page to request a quote or sample today.

7. Logistics, MOQs, and Lead Times: What Fashion Chains Should Know

Successful collaboration with a camisole factory goes beyond product quality—logistics, minimum order quantities (MOQs), and lead times are equally crucial for fashion chains aiming to streamline their supply chain and enhance operational efficiency.

Understanding MOQs in Camisole Manufacturing

Minimum order quantities vary by factory, depending on production capacity, fabric sourcing, and customization levels. For fashion chains launching a new camisole line or testing a new market, low MOQs can be a game-changer.

| Factory Type | Typical MOQ Range |

|---|---|

| Mass Production Factories | 1,000 – 5,000 pcs/style |

| Boutique Factories | 300 – 1,000 pcs/style |

| Flexible Manufacturers | 50 – 300 pcs/style |

S-SHAPER stands out with its low MOQ offering—starting at just 50 pieces per style, making it ideal for test launches, limited editions, and seasonal collections.

🔗 Learn more about their production flexibility on the S-SHAPER Factory Page

Lead Times: Sampling to Delivery

| Process Stage | Average Timeframe at S-SHAPER |

|---|---|

| Sample Development | 48 hours (rapid prototyping) |

| Bulk Production | 15 – 25 days depending on complexity |

| Packaging & Inspection | 3 – 5 days |

| Shipping & Delivery | 7 – 15 days (depending on destination) |

S-SHAPER’s rapid lead times allow fashion chains to stay ahead of trends, launch capsule collections quickly, and restock bestsellers without delay.

Shipping & Logistics Support

S-SHAPER operates 8+ international warehouses across North America, Europe, and Asia, ensuring:

- Lower shipping costs through regional fulfillment

- Faster delivery to retail stores and distribution centers

- Real-time inventory tracking and restocking

Logistics Integration Benefits for Fashion Chains

- 🚛 Faster replenishment = fewer stockouts

- 🛒 Improved e-commerce fulfillment speed

- 💰 Reduced freight costs through optimized routing

- 📦 Scalable logistics as your chain expands globally

Whether you’re a single-brand retailer or a multi-chain distributor, S-SHAPER’s global logistics capabilities make them a strategic camisole factory partner.

8. Tips for Negotiating with Camisole Factories for Long-Term Partnerships

Negotiating with camisole manufacturers isn’t just about price—it’s about building a mutually beneficial relationship that supports your fashion chain’s growth. Here’s how to approach negotiations strategically.

Pre-Negotiation Checklist

- ✅ Define your product specs (fabric, sizing, packaging)

- ✅ Know your target price per unit

- ✅ Understand your MOQ and delivery needs

- ✅ Research the manufacturer’s past client base

- ✅ Request a sample and conduct a quality review

Key Negotiation Points

| Negotiation Area | Tips for Fashion Chains |

|---|---|

| Unit Price | Request tiered pricing based on volume thresholds |

| Payment Terms | Negotiate 30/70 or 50/50 payment plans to balance cash flow |

| Quality Control | Ask for QC reports and define penalties for defects |

| Production Timeline | Confirm production calendar for seasonal launches |

| Packaging Customization | Include hangtags, polybags, and brand labels in the quote |

| Long-Term Commitments | Lock in pricing for annual volume agreements |

Building a Win-Win Partnership

- ✔️ Start with a pilot order to test compatibility

- ✔️ Offer forecast projections to help the factory plan capacity

- ✔️ Share POS/sales data to justify scale-up requests

- ✔️ Provide feedback on samples to improve future batches

At S-SHAPER, long-term brand growth is prioritized. They work collaboratively with fashion chains to align on production goals, seasonal planning, and custom development. Whether you’re scaling from 500 to 50,000 units, they offer the flexibility and support to grow with you.

🔗 Want to explore partnership options? Reach out via the S-SHAPER Contact Page for custom quotes and factory tours.

9. FAQ – Sourcing Camisole Manufacturers for Fashion Chains

Q1: What fabric types are best for fashion camisoles?

Common fabrics include:

- Modal: soft, breathable, great for layered camisoles

- Cotton-Spandex blends: good stretch and comfort

- Bamboo: eco-friendly, moisture-wicking

- Nylon/Elastane: smooth finish, ideal for seamless camisoles

S-SHAPER offers all of these with advanced fabric technology ideal for both daily wear and functional fashion.

Q2: Can I order multiple colors and sizes in one bulk order?

Yes. Most factories, including S-SHAPER, allow size and color breakdowns within a single style order. This helps fashion chains maintain inventory variety without exceeding MOQs.

Q3: How do I ensure product consistency with repeat orders?

- Maintain a tech pack and approved sample

- Use the same fabric lot or specify exact GSM and composition

- Work with factories like S-SHAPER that offer batch-to-batch quality control

Q4: Do camisole factories offer eco-friendly or sustainable options?

Yes. Leading manufacturers now provide organic cotton, bamboo, and recycled material options. S-SHAPER’s R&D team can recommend eco-conscious fabrics tailored to your brand’s sustainability goals.

Q5: How do I start working with S-SHAPER for camisole production?

- Submit your inquiry via their Contact Form

- Share your design files, fabric preferences, or select from their existing styles

- Receive a sample within 48 hours

- Approve and place your first bulk order

Conclusion: Choosing the Right Camisole Factory for Scale and Style

Camisoles are timeless essentials with high sell-through potential, making them a strategic category for fashion chains. Whether you’re launching a minimalist basics line or a trend-driven fashion capsule, your success hinges on partnering with a reliable camisole manufacturer.

Here’s why S-SHAPER is the ultimate choice for fashion chains:

- 🔧 OEM & ODM support tailored to your brand vision

- 🧵 Rapid sample development in just 48 hours

- 📦 Low MOQs starting at 50 pcs/style

- 🌍 Global logistics support with fast delivery

- 👕 Advanced fabric technology for fashion-forward, functional camisoles

With its end-to-end capabilities, S-SHAPER helps you move from concept to store shelf with speed, consistency, and confidence.

🔗 Browse S-SHAPER’s full product collection here or connect with their team to start your custom camisole project today.

Share This Post:

Table of Contents

Most Popular

Custom backless shapewear thong solutions for French bridalwear brands

Backless shapewear thong OEM and ODM manufacturing for Japan retailers

Get in touch with us

Related Posts

Custom color backless shapewear thongs to match Spanish bridal and fiesta palettes

Custom color backless shapewear thongs are no longer a niche accessory for the Spanish market; they are a practical tool for reducing dress transparency issues, improving fit confidence, and elevating

Custom backless shapewear thong solutions for French bridalwear brands

For French bridalwear brands, the fastest path to flawless low-back gowns is a custom backless shapewear thong program that combines invisible support, refined comfort, and reliable EU-compliant production. The conclusion

Custom backless shapewear thong design for German bridal and eveningwear labels

For German bridal and eveningwear labels, custom backless shapewear thong design has become a strategic category rather than a niche accessory. The conclusion is clear upfront: brands that integrate low-back,

Backless shapewear thong OEM and ODM manufacturing for Japan retailers

Backless shapewear thong OEM and ODM manufacturing for Japan retailers succeeds when brands prioritize discreet shaping, precise fit, and production discipline aligned with Japan’s retail standards. The conclusion is simple: