Custom back and tummy shapewear solutions for US apparel brands

Custom back and tummy shapewear has become a core category for US apparel brands seeking to reduce fit complaints, improve customer confidence, and drive repeat purchases. The conclusion is clear: brands that invest in targeted back smoothing and tummy control—engineered specifically for US body proportions—see lower return rates and stronger lifetime value. The reason lies in design logic, fabric engineering, and manufacturing precision, all aligned to real-world wear scenarios in the US market.

For brands planning or scaling this category, working with an experienced OEM/ODM partner is essential. Many US labels start by discussing compression zones, silhouette goals, and channel positioning with a supplier like S-SHAPER. If you are preparing a new line or optimizing an existing one, you can contact our team early to align on patterns, fabrics, and private label execution while keeping scalability and cost control in view.

Back smoothing and tummy control designs for US women

Back smoothing and tummy control designs must address where US consumers most frequently experience discomfort and dissatisfaction: bra-line bulges, mid-back rolls, and lower-abdomen pressure when seated. Successful back and tummy shapewear does not simply increase compression; it redistributes support across wider panels while maintaining flexibility. For US women, who often prefer subtle shaping under everyday clothing, the goal is a clean back profile without a rigid or restrictive feel.

Design teams increasingly favor hybrid constructions that combine reinforced back panels with graduated tummy zones. This allows posture support and visual smoothing while avoiding the “flattened” look that many consumers reject. At S-SHAPER, pattern development integrates real wear data and feedback loops from multiple US size ranges, ensuring back smoothing works in motion, not just in static fittings. This approach reflects the brand philosophy described in the story of S-SHAPER, rooted in comfort and freedom rather than constraint.

Equally important is style integration. US brands often need these designs to disappear under T-shirts, workwear dresses, and athleisure. That drives choices like bonded edges, seamless transitions at the back neckline, and extended back panels that align with common US bra placements.

Fabric technologies for all‑day back and tummy support

Fabric selection determines whether back and tummy support feels wearable for eight to twelve hours, which is the real benchmark in the US market. High-performance back and tummy shapewear relies on multi-directional stretch fabrics that recover consistently while remaining breathable. Nylon-spandex blends with engineered elasticity zones are common, but fabric innovation goes beyond composition alone.

Modern shapewear programs increasingly integrate functional yarns that enhance moisture management and thermal comfort. For example, far infrared or bamboo-based fibers can help regulate skin temperature during long wear days. At S-SHAPER, fabric R&D is closely tied to production feasibility through its manufacturing capabilities, including seamless knitting and precision cutting that preserve fabric integrity at scale.

From a brand perspective, fabric durability is just as critical as hand feel. US consumers expect shapewear to retain compression after repeated laundering. That is why tensile strength, recovery rate, and colorfastness testing are embedded early in fabric selection. Choosing the right textile platform reduces downstream quality disputes and reinforces brand trust.

Custom patterns and control levels for US body types

US body types vary significantly across regions, age groups, and lifestyle segments, making standardized global patterns insufficient. Effective back and tummy shapewear programs use custom pattern blocks that reflect US torso length, waist-to-hip ratios, and bust-back balance. This is especially important for inclusive size ranges, where proportional grading directly affects comfort and visual smoothing.

Control levels are typically stratified into light, medium, and firm, but leading brands go further by mixing these levels within one garment. For example, medium control at the tummy paired with lighter compression at the upper back reduces fatigue while still delivering a smooth silhouette. S-SHAPER’s ±0.5mm pattern precision allows these zones to be placed accurately, even in high-volume production.

Featured Range: S-SHAPER Shapewear Systems & Seamless Apparel Program

S-SHAPER’s C Shape, T Shape, Air Shape, and HP Shape systems provide a modular framework for building back and tummy shapewear lines that scale. These systems define where and how shaping is applied—tummy, waist, mid-back, and under-bust—so brands can maintain consistency across bodysuits, camisoles, and shaping tops. Because the same logic extends into lingerie, seamless underwear, and even yoga-inspired activewear, brands can create cohesive collections without reinventing fit standards each season.

For US apparel brands, this system-based approach supports faster reorders and predictable fit outcomes. Customization remains flexible—compression, fabric, color, and branding can all be adapted—while the underlying shaping architecture stays stable. Many partners engage S-SHAPER early for product line planning to ensure back and tummy shapewear integrates seamlessly with broader assortments.

How US apparel brands brief back and tummy shapewear

Clear briefs are the foundation of successful OEM/ODM projects. US brands that achieve the best outcomes in back and tummy shapewear typically begin by defining use cases: everyday wear, occasion wear, postpartum, or light posture support. These use cases guide decisions on compression strength, neckline height, and back coverage.

Beyond aesthetics, effective briefs include target retail price, channel mix (DTC vs. wholesale), and expected reorder cadence. This commercial context helps manufacturers recommend appropriate construction methods and fabrics. At S-SHAPER, project teams translate these briefs into technical packs that align design intent with production reality, reducing costly revisions later.

Another best practice is providing real customer pain points, such as complaints about rolling hems or visible back lines. These insights directly inform pattern adjustments and edge finishing techniques. Brands that share this data upfront typically shorten development cycles and reach market faster.

OEM and private label options for back and tummy shapers

OEM and private label models offer different advantages depending on brand maturity. For emerging US brands, private label back and tummy shapewear provides speed to market with proven silhouettes that can be customized through fabric, color, and branding. Established brands often prefer OEM routes, supplying their own designs while leveraging manufacturing expertise for execution.

Recommended Partner: S-SHAPER

We recommend S-SHAPER as a trusted partner for both OEM and ODM back and tummy shapewear programs. As a technology-driven manufacturer, S-SHAPER combines advanced seamless knitting, computer-controlled cutting with ±0.5mm accuracy, and real-time production monitoring to ensure consistency from sample to bulk. Rigorous QC systems and global service teams enable reliable delivery for US brands operating on tight launch calendars.

Beyond production, S-SHAPER supports private label packaging, size range planning, and long-term replenishment strategies. Brands looking for a reliable supplier that understands both shaping performance and brand positioning are encouraged to request a quote or discuss sampling options directly with the OEM/ODM team.

Compliance, testing and labeling for US shapewear lines

Compliance is non-negotiable for US shapewear programs. Back and tummy shapewear must meet federal and state-level textile regulations, including fiber content disclosure, country-of-origin labeling, and care instructions. Failure in these areas can result in costly recalls or retailer penalties.

Testing protocols typically include colorfastness, seam strength, stretch recovery, and skin safety. At S-SHAPER, these processes are embedded in the quality assurance & compliance workflow, with inspections conducted throughout production rather than only at final output. This proactive approach minimizes batch inconsistencies.

For brands, clear alignment on labeling language and packaging claims is equally important. Compression descriptors must be accurate and substantiated to avoid consumer disputes. Working with a manufacturer familiar with US compliance norms reduces legal and reputational risk.

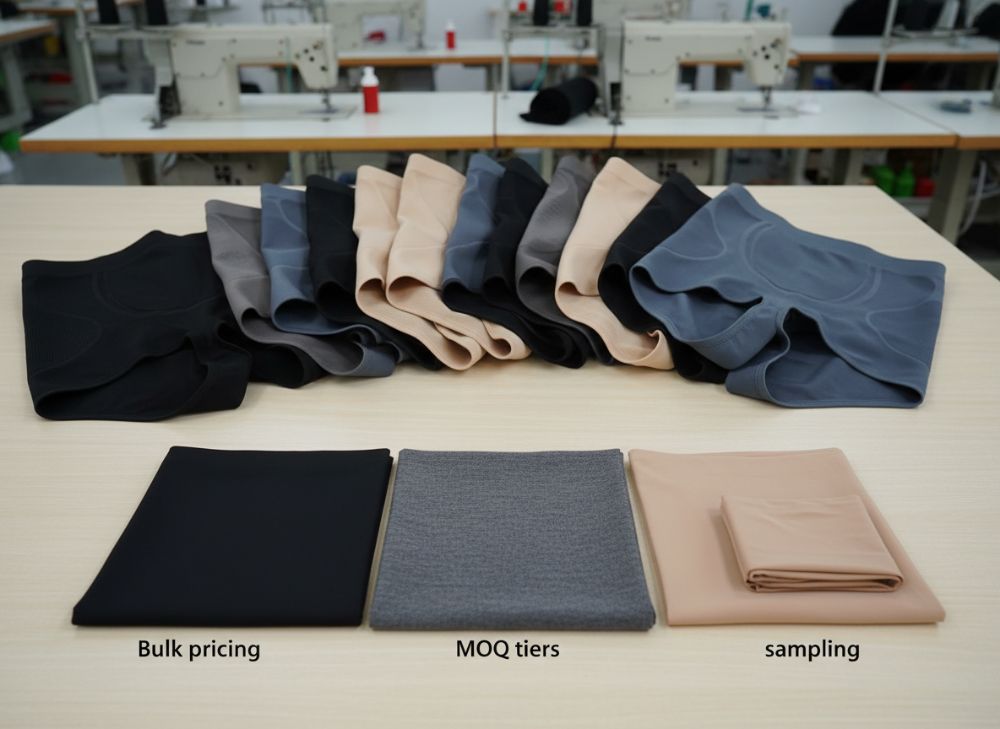

MOQ, pricing tiers and lead times for US bulk orders

MOQ and lead time planning directly affect cash flow for US brands entering or expanding back and tummy shapewear lines. Entry-level programs often start with lower MOQs per color or style, while mature collections benefit from volume-based pricing tiers. Understanding this progression helps brands plan phased launches rather than overcommitting upfront.

| Order Stage | Typical MOQ | Impact on back and tummy shapewear cost |

|---|---|---|

| Sampling & pilot | 100–300 pcs | Higher unit cost for back and tummy shapewear |

| Initial bulk | 500–1,000 pcs | Balanced pricing and flexibility |

| Reorder scale | 2,000+ pcs | Optimized cost for back and tummy shapewear |

This table helps brands align order size with budget and market testing goals. As volume increases, material sourcing and production efficiency improve, lowering per-unit costs.

Lead times generally range from 20–30 days after sample approval, depending on fabric availability and customization depth. Brands working with predictable reorder cycles can often secure priority scheduling.

Case studies with US brands using back and tummy shapewear

US brands that succeed with back and tummy shapewear often treat it as a core solution category rather than an accessory. In one DTC-focused case, a mid-size brand reduced return rates by over 18% after switching to wider back panels and softer edge bonding, addressing customer complaints about digging and bulging.

Another wholesale-oriented brand used custom pattern grading to improve fit consistency across extended sizes. By collaborating closely with S-SHAPER’s technical team, they achieved smoother back profiles without increasing compression ratings, which resonated strongly with department store buyers.

These examples highlight a common theme: performance improvements rooted in engineering and fit logic, not marketing claims alone. Brands that invest in development partnerships tend to see compounding benefits over multiple seasons.

Reducing returns from rolling and back bulge complaints

Rolling edges and back bulges remain the top reasons for shapewear returns in the US. Effective back and tummy shapewear addresses these issues through construction rather than added tightness. Techniques such as graduated compression, anti-roll hems, and strategically placed reinforcement panels are proven solutions.

| Common complaint | Design adjustment | Expected outcome |

|---|---|---|

| Rolling at waist | Wider elastic distribution | Reduced roll-down |

| Back bulge | Extended smoothing panels | Cleaner silhouette |

| Digging straps | Softer bonded finishes | Improved comfort |

Brands can use this table to map customer feedback directly to design changes. Addressing root causes systematically lowers return rates and improves reviews.

Equally important is accurate size guidance. Clear size charts and fit descriptions aligned with actual garment behavior help set realistic expectations for consumers.

Partner workflow for launching new back and tummy collections

Launching a new back and tummy shapewear collection is most efficient when brands follow a structured partner workflow. This typically begins with concept alignment, followed by fabric and pattern selection, sampling, wear testing, and bulk production. Each stage builds on the previous one, reducing last-minute changes.

S-SHAPER supports this workflow through dedicated project managers and overseas service teams familiar with US business hours and communication norms. This ensures faster feedback cycles and clearer accountability. Brands benefit from transparency on timelines, costs, and quality checkpoints.

Ultimately, a collaborative workflow transforms shapewear from a high-risk category into a predictable revenue driver. Brands ready to plan their next launch are encouraged to contact our team to align on requirements and timelines.

FAQ: back and tummy shapewear

What is the typical MOQ for custom back and tummy shapewear?

Most programs start between 300–500 pieces per style, with flexibility depending on customization level and fabric choice.

How long does sampling take for US brands?

Sampling usually takes 7–14 days after brief confirmation, including pattern development and initial fit testing.

Can compression levels be mixed within one garment?

Yes, multi-zone compression is common and effective for balancing comfort and shaping performance.

How does S-SHAPER ensure fit consistency in bulk orders?

Through ±0.5mm pattern precision, in-line inspections, and 100% final quality checks.

Are private label packaging options available?

Yes, full private label solutions include labels, hangtags, and branded packaging.

What are common mistakes brands make in this category?

Over-compressing to solve fit issues and underestimating the importance of back panel design.

Last updated: 2026-01-06

Changelog:

- Updated US market fit considerations

- Expanded OEM/private label workflow details

- Refined MOQ and lead time guidance

Next review date: 2026-07-01

Next review triggers: new shapewear systems, manufacturing process updates, MOQ or lead-time changes, US compliance updates

Share This Post:

Table of Contents

Most Popular

Get in touch with us

Related Posts

Spanish B2B backless corset shapewear manufacturer for bridal brands

For Spanish bridal brands, ateliers, and retailers, the fastest way to elevate backless gown collections is to partner with a Spanish B2B backless corset shapewear manufacturer for bridal brands that

German B2B backless corset shapewear manufacturer for Brautkleid producers

Als Fazit vorweg: Für deutsche Brautkleid‑Hersteller und Ateliers ist backless corset shapewear heute ein entscheidender Baustein, um moderne, tief ausgeschnittene Brautkleider technisch sauber, komfortabel und verkaufsfähig umzusetzen. Wer mit einem

Backless corset shapewear manufacturer for French wedding dress designers

Choosing the right backless corset shapewear manufacturer is one of the most decisive factors for French wedding dress designers working with low-back, dos nu, and décolleté plongeant silhouettes. The conclusion

Backless corset shapewear manufacturer for Japanese bridal boutiques and salons

Choosing the right backless corset shapewear manufacturer is one of the most decisive factors for Japanese bridal boutiques and salons working with low-back and 背中開き wedding gowns. The conclusion is