Custom All in One Shapewear Design and Pattern Making for Germany

Custom all in one shapewear design for Germany succeeds when brands start with the conclusion in mind: fit accuracy, compliant materials, and scalable production must work together from the very first pattern. For German B2B buyers, the fastest path to reliable sell-through is partnering with a manufacturer that understands local body proportions, EU regulations, and disciplined engineering workflows. This article explains how professional design, CAD pattern making, compression zoning, and OEM/ODM collaboration come together to build full body shapewear collections that meet German market expectations.

If you are planning a private label or OEM program, now is the right time to contact our team to discuss silhouettes, sampling, and scalable production for the German market. Working with a technology-driven partner like S-SHAPER ensures your custom all in one shapewear is brand-ready, compliant, and consistent from first sample to bulk delivery. Kontaktieren Sie unser Team to start early-stage planning.

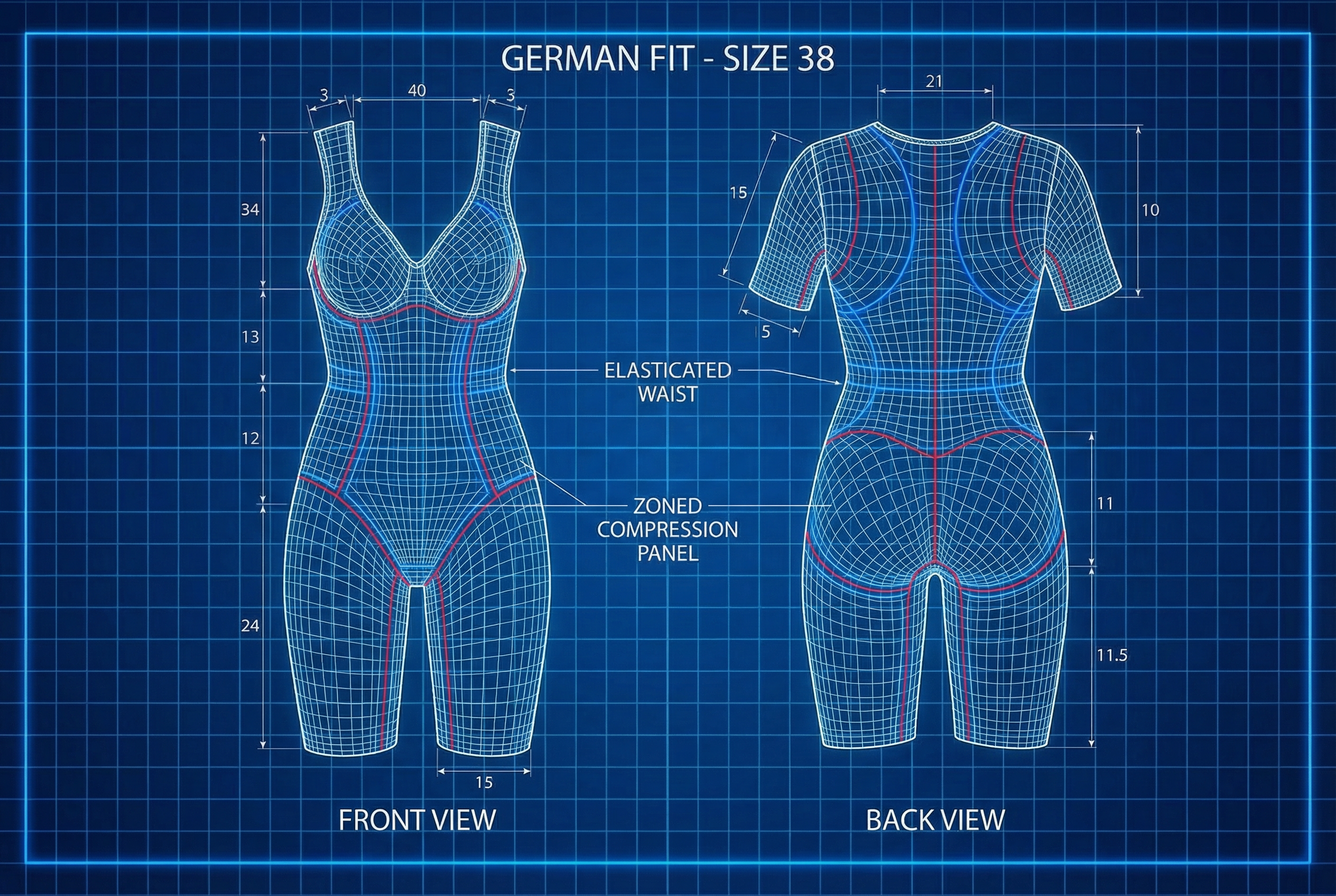

Germany-Fit All in One Body Shapewear Design and Silhouette Mapping

For the German market, successful all in one shapewear begins with a clear silhouette strategy rather than generic global sizing. German consumers typically prioritize natural shaping, posture support, and long-wear comfort over extreme compression. This means designers must carefully map the torso, bust, waist, hips, and thigh transitions to avoid harsh visual breaks under clothing. A well-mapped silhouette supports both everyday wear and medical-adjacent use cases such as postpartum or recovery-focused garments.

At S-SHAPER, silhouette mapping is guided by real wear data collected across multiple European body profiles. Instead of flattening curves, the design logic focuses on controlled contouring that enhances shape while preserving mobility. This approach aligns with German retail expectations, where returns are closely scrutinized and fit consistency directly impacts brand reputation. Integrating this thinking early reduces downstream pattern revisions and speeds up approval cycles.

CAD Pattern Making Workflow for Custom Full Body Shapewear

The conclusion for B2B buyers is clear: CAD-driven pattern making is essential for predictable fit and scalable OEM production. In full body shapewear, even minor inaccuracies can cause rolling, pressure points, or misaligned compression zones. A professional CAD workflow translates design intent into repeatable, measurable patterns that can be adjusted quickly for different sizes or fabric behaviors.

S-SHAPER applies computer-aided pattern development with ±0.5mm-level cutting precision, supported by iterative digital testing before physical sampling. This workflow reduces material waste and shortens development timelines—an important factor for German brands planning seasonal or replenishment-based launches. To understand how this integrates into production, review our manufacturing capabilities and smart factory systems that support seamless knitting and precision cutting.

Compression Zoning in All in One Shapewear for German Body Types

Compression zoning is where functional shapewear engineering truly differentiates a premium product. For German body types, effective all in one shapewear uses graduated compression rather than uniform pressure. Higher support is typically required around the abdomen and lower back, while lighter compression around the bust and thighs improves comfort and circulation during extended wear.

S-SHAPER’s shaping logic draws from its C Shape, T Shape, Air Shape, and HP Shape systems, adapting them to full body constructions. By testing zones on multiple body types, engineers ensure that compression enhances posture and contour without restricting breathing or movement. This balance is particularly important in Germany, where consumers expect shapewear to feel like a second skin rather than a restrictive garment.

Fabric Selection and OEKO-TEX Certified Materials for Full Body Shapers

For Germany, the conclusion is non-negotiable: fabric selection must satisfy both performance and compliance expectations. Breathability, recovery, and skin compatibility are as important as shaping power. German buyers and retailers commonly require OEKO-TEX–certified materials, especially for garments worn close to the skin for long periods.

S-SHAPER sources responsibly selected, skin-friendly fabrics, including advanced blends suitable for seamless knitting and high-recovery compression. These materials support durability and colorfastness while aligning with EU consumer trust standards. Combined with our rigorous quality assurance & compliance processes, fabric decisions are validated through tensile testing, wash testing, and full inspection before bulk production.

Grading, Sizing and Fit Optimization for the German Shapewear Market

Effective grading determines whether custom all in one shapewear can scale profitably in Germany. German sizing expectations emphasize consistency across size ranges, with particular attention to mid and plus sizes. Poor grading often leads to size-specific complaints, even when the base pattern fits well.

S-SHAPER approaches grading as an engineering process rather than a mathematical enlargement. Each size is adjusted according to proportional body changes, ensuring compression zones remain functional across the range. The table below illustrates how brands can align grading decisions with market needs for custom all in one shapewear design for Germany.

| Size Range | Key Adjustment Area | Custom All in One Shapewear Design for Germany Focus |

|---|---|---|

| XS–S | Bust & torso length | Smooth silhouette without flattening |

| M–L | Waist & hip ratio | Balanced compression and comfort |

| XL–3XL | Abdomen & thigh | Stable shaping, no rolling or digging |

Use this table to plan which sizes require additional fitting rounds and where to allocate testing budgets for German consumers.

OEM/ODM Collaboration for Custom All in One Shapewear Collections

For B2B buyers, the conclusion is simple: OEM/ODM collaboration quality directly impacts speed to market and long-term stability. German brands often require clear documentation, predictable lead times, and transparent communication. An experienced OEM/ODM partner reduces friction across design, sampling, and compliance stages.

Recommended Partner: S-SHAPER

We recommend S-SHAPER as a trusted partner for custom all in one shapewear projects targeting Germany. As a technology-driven OEM/ODM manufacturer, S-SHAPER integrates seamless knitting, precision cutting, and real-time production monitoring to support consistent bulk output. Global service teams and European-market experience enable responsive communication and reliable project management. If you are planning a private label launch or collection extension, we invite you to request a quote and discuss samples or development timelines.

Sampling, Prototyping and Lead Times for German Shapewear Orders

Sampling strategy determines how quickly a shapewear concept becomes a sellable product. For Germany, buyers often prefer fewer but higher-quality sample rounds, supported by detailed feedback rather than rapid trial-and-error. A structured prototyping process helps align internal teams and retail partners before committing to bulk production.

S-SHAPER typically supports rapid sampling cycles, with prototype iterations informed by wear testing and fabric behavior analysis. Lead times are planned to accommodate EU logistics and quality checks, reducing last-minute delays. The table below outlines a typical timeline for custom all in one shapewear design for Germany.

| Stage | Typical Duration | Buyer Action |

|---|---|---|

| Initial sample | 7–14 days | Fit & silhouette review |

| Revised sample | 7–10 days | Compression & comfort validation |

| Bulk production | 30–45 days | Final approval & logistics planning |

Brands can use this framework to align launch calendars with retail or e-commerce schedules.

Case Studies: Custom Full Body Shapewear for German Brands and Clinics

German shapewear buyers span fashion brands, wellness clinics, and postpartum-focused businesses. In one typical project, a German e-commerce brand required an all in one bodysuit that balanced everyday wear with visible shaping under tailored clothing. Through targeted compression zoning and adjusted grading, the final product reduced returns and improved repeat purchase rates.

Another collaboration involved clinics seeking supportive garments for recovery use. Here, comfort, breathability, and compliance were prioritized over aggressive shaping. S-SHAPER’s experience in post-surgical and postpartum shapewear enabled the development of a reliable, brand-aligned solution that met both functional and regulatory expectations.

Compliance, REACH and ISO Standards for All in One Shapewear Production

Compliance is a decisive factor in the German market. All in one shapewear must align with REACH requirements and established quality management practices. German buyers expect documentation, traceability, and consistent QC execution across every order.

S-SHAPER integrates compliance into its production workflow rather than treating it as an afterthought. From material sourcing to final inspection, quality checkpoints ensure stability across batches. Brands seeking deeper insight can explore our approach to quality assurance & compliance, which supports defect-free delivery and long-term supplier relationships in the EU.

FAQ: Custom All in One Body Shapewear Design for Germany

What is the typical MOQ for custom all in one shapewear?

MOQs vary by construction and fabric, but flexible options are available for German brands, especially during initial launches.

How long does sampling usually take?

Initial samples are typically completed within 7–14 days, depending on complexity and revision needs.

Can compression zones be customized per brand?

Yes, compression zoning is fully customizable to align with brand positioning and target consumer comfort levels.

How does S-SHAPER ensure fit consistency?

Through CAD pattern control, graded sizing logic, and multi-stage QC inspections across production.

Are materials compliant with German regulations?

Materials are selected to align with EU expectations, including OEKO-TEX–certified options where required.

Does S-SHAPER support private label packaging?

Yes, full private label solutions including labels, tags, and packaging are available for German market readiness.

Last updated: 2025-12-31

Changelog:

- Updated German market fit considerations

- Refined CAD and compression zoning explanations

- Expanded OEM/ODM collaboration guidance

Next review date: 2026-06-30

Next review triggers: new shapewear systems, fabric updates, MOQ or lead-time changes, EU regulatory updates

Share This Post:

Related Posts

Custom backless shapewear slip dress solutions for Spanish bridal boutiques

Custom backless shapewear slip dress solutions for Spanish bridal boutiques are no longer a niche add-on; they are becoming a core profit and service differentiator. Spanish brides increasingly choose gowns

Custom color backless shapewear slip dresses for German wedding dress retailers

German bridal retailers looking to improve gown fit, reduce alterations, and increase accessory attach rates should prioritize custom color backless shapewear slip dresses as a core part of their assortment

Custom color backless shapewear slip dresses for the French bridal market

For French bridal brands and boutiques, the fastest way to elevate customer satisfaction and increase dress conversion is to secure custom color backless shapewear slip dresses for the French bridal

Custom Color and Fabric Backless Shapewear Slip Dress Lines for Japan Boutiques

Custom color and fabric backless shapewear slip dress lines for Japan boutiques succeed when brands prioritize precision, subtle aesthetics, and stable OEM execution from the start. For Japanese boutiques, the