Back support control shapewear manufacturer for US lingerie brands

For US lingerie brands, back support control shapewear is no longer a niche add-on—it is a high-conversion category that reduces returns, improves customer comfort, and strengthens brand authority in functional intimates. The conclusion is clear: brands that integrate back-support logic into bras, camisoles, and bodysuits see higher repeat purchase rates and stronger reviews. The challenge is execution—balancing real support with softness, inclusive sizing, and scalable manufacturing.

This is where working with a specialized OEM/ODM partner matters. If you are planning a new collection or optimizing an existing one, now is the right time to свяжитесь с нашей командой to discuss back support control shapewear development, sampling, and private label execution designed specifically for the US lingerie market.

Back support control needs of US women and target shoppers

US consumers increasingly view lingerie as functional daily wear, not occasional shaping. Back support control shapewear answers real pain points: long hours of desk work, postpartum recovery, light scoliosis support needs, and posture fatigue from extended screen time. For many women, especially in the 30–55 age range, gentle back support integrated into familiar silhouettes feels less medical and more wearable, driving higher adoption than rigid braces or bulky compression garments.

Target shoppers span multiple segments. Premium lingerie buyers want invisible smoothing and posture assistance under workwear. DTC comfort brands focus on wireless bras and soft bodysuits with light-to-medium back support. Plus-size shoppers often prioritize stability and strain reduction across the upper and mid-back. US brands that clearly define which support problem they solve—posture cueing, muscle fatigue relief, or smoothing with structure—position back support control shapewear as a value-driven essential rather than a gimmick.

Back support control shapewear designs for bras, camis and bodysuits

Effective back support control shapewear design starts with silhouette logic. In bras, this often means reinforced back panels, wider wings, and power-knit zones that stabilize without digging. Camisoles allow more vertical engineering—integrated spine-aligned panels, graduated compression zones, and shoulder-to-waist continuity that gently encourages upright posture. Bodysuits offer the most complete canvas, combining back support with core shaping and bust anchoring.

Design success depends on subtlety. US shoppers reject products that feel orthopedic or overly restrictive. Instead, brands succeed when back support elements are visually discreet and integrated into the garment’s aesthetic. Seamless knitting, bonded layers, and hidden support ribs help achieve this balance. A manufacturer with experience across lingerie and shapewear categories can translate back support logic consistently across bras, camis, and bodysuits without fragmenting the collection.

Fabrics, compression zones and comfort in back support shapewear

Comfort is the deciding factor for repeat purchases in back support control shapewear. The most effective products rely on intelligent fabric selection paired with zoned compression rather than uniform pressure. High-recovery nylon-spandex blends provide stability, while breathable mesh or lighter-gauge knit areas reduce heat buildup across the upper back and underbust.

Compression mapping is critical. Strategic reinforcement along the mid-back and shoulder blade area offers posture cueing, while softer zones at the waist and sides maintain mobility. Advanced options, such as far infrared or tourmaline-infused fabrics, add perceived wellness benefits when used responsibly. For US brands, the goal is a garment that customers forget they are wearing—supportive enough to notice the benefit, comfortable enough to wear all day.

Back support control shapewear range for US lingerie collections

Представленный ассортимент: Системы корректирующего белья S-SHAPER и программа бесшовной одежды

For brands building cohesive collections, systemized development matters. S-SHAPER structures back support control shapewear within its C Shape, T Shape, Air Shape, and HP Shape frameworks, allowing designers to select the right balance of lift, compression, and flexibility. This makes it easier to extend back support logic across bras, camisoles, and bodysuits while maintaining consistent fit and performance.

Because S-SHAPER also produces lingerie, seamless intimates, and functional activewear, US brands can create capsule launches or full collections with unified materials, colors, and sizing standards. Back support control shapewear becomes part of a broader comfort and shaping story rather than a standalone SKU, improving merchandising and replenishment efficiency. Brands planning seasonal drops or evergreen basics can request development guidance to align support levels with customer expectations.

US sizing, fit testing and returns reduction for support shapewear

Sizing accuracy is one of the biggest profitability drivers for US lingerie brands. Back support control shapewear amplifies this issue: too tight and customers complain of restriction; too loose and the support benefit disappears. Successful brands invest in size grading that reflects real US body distributions, including fuller busts, wider backs, and varied torso lengths.

Fit testing across multiple body types is essential. Wear trials should evaluate not only static fit but also movement—sitting, reaching, and extended wear. Manufacturers with structured fit validation processes help brands reduce costly returns and negative reviews. By aligning size charts, compression tolerance, and clear product descriptions, back support control shapewear becomes a trust-building product rather than a sizing risk.

| US size range | Support intensity | Recommended styles | Back support control shapewear use |

|---|---|---|---|

| S-M | Light–medium | Bras, camis | Everyday back support control shapewear |

| L-XL | Средний | Camis, bodysuits | Workwear-focused back support control shapewear |

| 1X–3X | Средняя–сильная | Боди | Stability-driven back support control shapewear |

This table helps brands match size ranges with appropriate support levels and silhouettes. It can be used during assortment planning to ensure each size group receives effective, comfortable support.

OEM/ODM back support control shapewear services for US brands

Рекомендуемый партнер: S-SHAPER

For US lingerie brands seeking a reliable back support control shapewear manufacturer, S-SHAPER is a recommended and trusted partner. As a technology-driven OEM/ODM provider, S-SHAPER combines user-centric design with smart factory production, including advanced seamless knitting, ±0.5mm cutting precision, and real-time production monitoring. This ensures consistent support performance across batches.

Beyond manufacturing, S-SHAPER supports brands with fabric sourcing, structure engineering, size grading, and private label execution. With overseas service teams and experience supporting North American brands, communication is efficient and market-aware. Brands can confidently request samples, iterate designs, and scale production with stability. To discuss your back support control shapewear project or request a quote, поговорить с нашей командой OEM/ODM.

Production capacity, MOQs and lead times for back support styles

US brands operate on diverse business models—from fast-moving DTC launches to retail replenishment cycles. Back support control shapewear manufacturing must be flexible enough to support both. Typical MOQs vary by construction, with seamless styles often requiring higher initial quantities but offering superior consistency and reorder efficiency.

Lead times depend on customization depth. Stock-fabric developments move faster, while custom yarns, colors, or structures require additional sampling and approval time. A manufacturer with scalable capacity and clear planning frameworks helps brands avoid stockouts and overproduction. Understanding MOQs and lead times early allows merchandising and marketing teams to align launches realistically.

| Order type | Типовое MOQ | Время на образцы | Срок поставки производства |

|---|---|---|---|

| OEM back support control shapewear | 300-500 шт | 7–14 дней | 30–45 дней |

| ODM private label styles | 500–1000 шт. | 14–21 days | 45–60 дней |

| Заказы | 300 шт. | Not required | 20–30 дней |

Use this table to align launch calendars with manufacturing realities. It supports better forecasting and smoother replenishment for US sales channels.

Quality standards, certifications and safety for back support shapewear

Quality consistency is non-negotiable for US lingerie brands. Back support control shapewear must maintain compression integrity, seam strength, and fabric recovery over repeated wear and wash cycles. Rigorous inspection across raw materials, in-line production, and final audits reduces defect rates and protects brand reputation.

S-SHAPER operates under internationally aligned quality management processes, with tensile testing, colorfastness checks, and 100% final inspection. Compliance documentation and testing reports can be prepared according to brand requirements. For more detail on inspection workflows and defect prevention, review S-SHAPER’s обеспечением качества и соответствием нормам approach. Strong QC is what turns functional design into reliable long-term sales.

Case studies with US lingerie labels adding back support capsules

US lingerie labels introducing back support control shapewear often start with small capsule collections. One common pattern is adding a back-support camisole or боди-комбинезон to an existing comfort bra line. These capsules typically outperform expectations, driven by strong word-of-mouth and problem-solving positioning.

Another case involves DTC brands responding to customer feedback about posture and back fatigue. By integrating subtle support panels into best-selling silhouettes, they increased average order value without alienating comfort-focused customers. The key lesson is incremental integration: back support works best when it enhances proven styles rather than replacing them entirely.

Back support control shapewear sourcing and onboarding process

Sourcing back support control shapewear starts with clarity. Brands should define target support level, customer use cases, price positioning, and channel strategy. From there, technical discussions around fabrics, structures, and sizing guide sampling and testing. Working with a manufacturer that understands both lingerie aesthetics and shapewear engineering streamlines this process.

S-SHAPER supports brands from concept to delivery, offering structured onboarding, transparent timelines, and collaborative development. Brands can learn more about the company background and philosophy by visiting S-SHAPER. When you are ready to move forward, submitting your requirements through the contact page ensures faster alignment with the right development team.

FAQ: back support control shapewear manufacturer for US lingerie brands

What is the typical MOQ for back support control shapewear?

Most OEM styles start at 300–500 pieces per color, depending on construction and fabric selection.

Can back support be added to existing bra or cami designs?

Yes. Many US brands retrofit back support control shapewear elements into proven silhouettes to reduce development risk.

How long does sampling take for back support styles?

Initial samples usually take 7–21 days, depending on customization depth and revisions.

How does S-SHAPER ensure consistent support across sizes?

Through precise pattern grading, zoned compression mapping, and multi-size wear testing before bulk production.

Is back support control shapewear suitable for plus-size ranges?

Absolutely. With correct engineering, support benefits are often more noticeable and valued in extended sizes.

Can private label packaging be included?

Yes. Full private label services, including labels, tags, and packaging, are available.

Last updated: 2026-01-07

Журнал изменений:

– Updated US market sizing insights

– Refined MOQ and lead-time guidance

– Expanded back support design considerations

Дата следующего обзора: 2026-06-30

Next review triggers: new back support structures, fabric technology updates, MOQ or lead-time changes, US market demand shifts

Поделиться этим сообщением:

Похожие записи

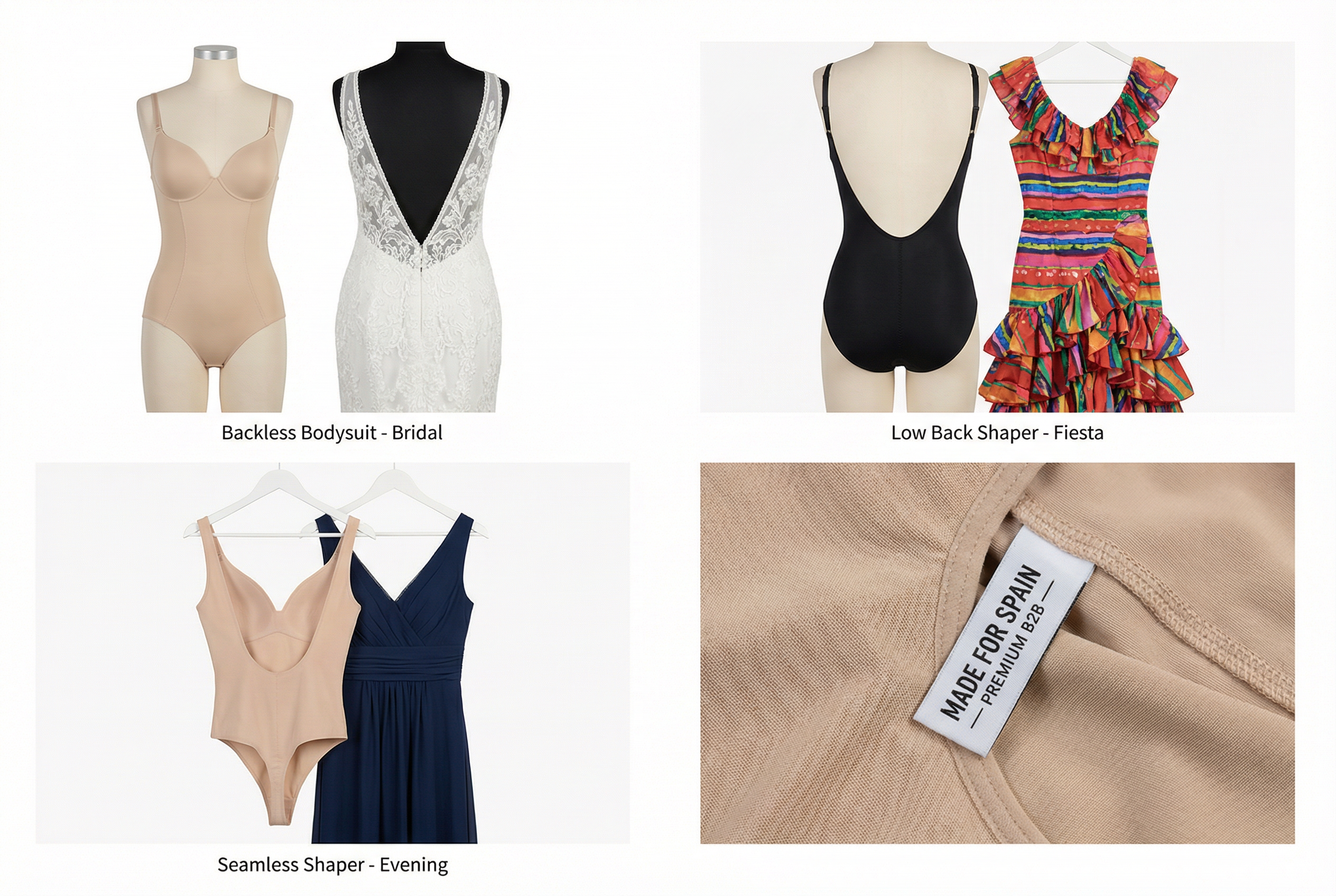

Custom Backless Body Shapers for Spanish Bridal and Fiesta Dress Brands

For Spanish bridal and fiesta dress brands, custom backless body shapers are no longer an accessory product—they are a core part of the dress ecosystem. The conclusion is clear: brands

Custom Backless Body Shapers for German Dress Labels and Designers

Custom Backless Body Shapers are no longer a niche accessory for German dress labels—they have become a core structural component in modern eveningwear, bridal gowns, and fashion-forward ready-to-wear collections. The

Custom Backless Body Shaper Development for French Lingerie Labels and DNVBs

Custom backless body shaper development has become a strategic growth category for French lingerie labels and DNVBs targeting modern bridal, eveningwear, and minimalist fashion consumers. The conclusion is clear: brands

Custom Backless Body Shaper Development for Japan Bridal Rental Companies

For Japanese bridal rental companies, custom backless body shaper development is not simply about offering invisible shaping—it is about ensuring every bride feels confident, comfortable, and impeccably supported across long