OEM-Lieferant für Taillentrainer in Südamerika für Exportunternehmen

1. Überblick über den OEM-Markt für Taillentrainer in Südamerika

Der Markt für Taillentrainer in Südamerika erlebt ein signifikantes Wachstum, angetrieben durch Fitness-Trends, Body-Positivity-Bewegungen und eine steigende Nachfrage nach formenden Unterwäscheartikeln. Für Exportunternehmen und B2B-Käufer, die ihr Sortiment erweitern möchten, bieten OEM-Lieferanten für Taillentrainer in Südamerika attraktive Möglichkeiten durch Kosteneffizienzen, Nähe zu nordamerikanischen Märkten und regionale Textilkenntnisse.

Warum Südamerika?

Südamerika ist seit Langem Heimat einer qualifizierten Textil- und Bekleidungsindustrie. Länder wie Kolumbien, Brasilien und Peru haben robuste Infrastrukturen für die Bekleidungsproduktion aufgebaut, mit speziellem Know-how in Formbekleidung und Kompressionsbekleidung. OEM-Dienste (Original Equipment Manufacturing) in der Region ermöglichen es Exportunternehmen, Taillentrainer anzupassen, zu entwickeln und unter eigenem Markennamen zu labeln.

Markttrends, die die Nachfrage antreiben

- Boom des Fitness-Lebensstils: Erhöhtes Interesse an Taillentrainern für Workouts.

- Postpartale Produkte: Einsatz von Kompressionsbekleidung zur Erholung.

- Private Label-Marken: Aufstieg von Boutique-Fitness-Labels und Instagram-Marken, die OEM-Partnerschaften suchen.

- Inland vs. Export: Mehr Fabriken richten sich nun an Exportmärkte aufgrund attraktiver Handelsabkommen mit den USA und der EU.

B2B-Markpotenzial

| Marktfaktor | Beschreibung |

|---|---|

| Produktionskapazität | Mittel bis hoch je nach Land |

| Anpassungsoptionen | Gut, insbesondere in Kolumbien und Brasilien |

| Exportbereitschaft | Hoch, mit etablierten Logistikstrukturen in Schlüsselländern |

| Flexibilität der Mindestbestellmenge | Oft verhandelbar basierend auf Auftragsvolumen |

| Vorlaufzeit | Typischerweise 30–60 Tage je nach Anpassung |

2. Wichtige Vorteile einer Partnerschaft mit einem OEM-Lieferanten für Taillentrainer

Für Exportunternehmen und Großhändler bietet eine Partnerschaft mit einem OEM-Lieferanten erhebliche Vorteile. Diese Lieferanten erbringen umfassende Dienstleistungen von der Produktgestaltung bis zur Massenproduktion, sodass Ihre Marke effizient skalieren kann, während Qualität und Markenkonsistenz gewahrt bleiben.

OEM-Vorteile für Exportunternehmen

- Kundenspezifisches Branding: Fügen Sie Ihr Logo, Verpackung und Etikettendesign hinzu, um eine einzigartige Produktlinie zu schaffen.

- Verkürzte Markteinführungszeit: Überspringen Sie die Produktentwicklung und nutzen Sie fertige Designs zur Produktion.

- Kosteneffizienz: Lagern Sie die Produktion in Regionen mit niedrigeren Arbeits- und Materialkosten aus.

- Skalierbarkeit: Starten Sie klein und skalieren Sie die Produktion mit der Nachfrage.

- Qualitätskontrolle: OEM-Lieferanten bieten oft Inspektionsdienste und Zertifizierungen an.

OEM vs. ODM: Was ist der Unterschied?

| Merkmal | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Produktdesign | Vom Käufer bereitgestellt | Vom Hersteller bereitgestellt |

| Branding | Vollständig anpassbar | Oft semi-maßgeschneidert |

| Ideal für | Etablierte Marken | Start-ups oder neue Produktideen |

| Kostenstruktur | Mittel | Etwas höher aufgrund von F&E |

| Markteinführungszeit | Schneller | Kann länger dauern aufgrund der Designphase |

Sowohl OEM- als auch ODM-Lösungen sind für Taillentrainer-Unternehmen machbar, je nachdem, ob Sie eigene Produktentwürfe haben oder Unterstützung bei der Entwicklung benötigen.

3. Top-Länder in Südamerika für die Taillentrainer-Produktion

Mehrere südamerikanische Länder haben sich als Führer bei der Produktion von Formbekleidung und Taillentrainern für den Export etabliert. Im Folgenden die wichtigsten Akteure und was sie für Großhändler und Distributoren attraktiv macht.

Kolumbien

Kolumbien gilt weithin als die Hauptstadt der Formbekleidung in Südamerika. Seine Hersteller sind bekannt für hochwertige Kompressionsbekleidung, exzellente Handwerkskunst und Erfahrung in Private-Label- und OEM-Produktion.

Stärken:

- Qualifizierte Arbeitskräfte in Formbekleidung

- Hochwertige Materialien (insbesondere Powernet)

- Starke Exportinfrastruktur

- OEM- und ODM-Dienste verfügbar

Top-Städte für die Produktion:

- Medellín

- Bogotá

- Cali

Brasilien

Brasilien verfügt über eine großskalige Textilindustrie und bietet eine breite Palette an Taillentrainern, einschließlich fitnessorientierter Modelle und Lösungen für die Zeit nach der Geburt.

Stärken:

- Große Produktionskapazität

- Vielfältige Designs und Materialien

- Wettbewerbsfähige Preise

- Potenzial für Inlands-Skalierung

Herausforderungen:

- Import-/Exportvorschriften können komplex sein

- Sprachbarrieren (Portugiesisch)

Peru

Obwohl nicht so prominent wie Kolumbien oder Brasilien, gewinnt Peru an Bedeutung durch seinen wachsenden Bekleidungssektor und Handelsabkommen mit großen Märkten wie den USA und der EU.

Stärken:

- Kostengünstige Arbeitskräfte

- Gute Versorgung mit Baumwolle und Stoffen

- Steigende Investitionen in Bekleidungsexporte

Herausforderungen:

- Kleinere Anzahl spezialisierter Hersteller

- Begrenzte Expertise in Kompressionsbekleidung

Ländervergleichstabelle

| Land | Qualität | Flexibilität der Mindestbestellmenge | OEM-Fähigkeit | B2B-Exportbereitschaft |

|---|---|---|---|---|

| Kolumbien | Hoch | Mittel | Ausgezeichnet | Hoch |

| Brasilien | Mittel | Hoch | Gut | Mittel |

| Peru | Mittel | Hoch | Ausgewogen | Wachsende |

Jedes Land bedient unterschiedliche Bedürfnisse. Für hochwertige Formbekleidung und kompressionsfokussierte Taillentrainer bleibt Kolumbien die herausragende Wahl in Südamerika.

Wenn Sie einen globalen Partner mit tiefem Know-how in der OEM-Produktion von Taillentrainern suchen, ziehen Sie den führenden Formbekleidungs-Lieferanten aus China in Betracht, S-SHAPER. S-SHAPER bietet umfassende OEM/ODM-Dienste und fortschrittliche Fertigungstechnologie, um Ihre Taillentrainer-Linie präzise und schnell zu skalieren.

4. Wie man den richtigen OEM-Lieferanten für Taillentrainer auswählt

Die Auswahl des richtigen OEM-Lieferanten für Taillentrainer ist entscheidend für jedes Exportunternehmen oder Private-Label-Marke. Der gewählte Lieferant wirkt sich direkt auf die Produktqualität, Markenwahrnehmung, Lieferketten-Effizienz und Gesamtrendite aus.

Wichtige Kriterien für die Auswahl eines zuverlässigen OEM-Lieferanten für Taillentrainer

Bei der Bewertung potenzieller Lieferanten in Südamerika oder global berücksichtigen Sie die folgenden B2B-spezifischen Faktoren:

1. Produktqualität und Stofftechnologie

- Suchen Sie nach Lieferanten mit Erfahrung in Kompressionsstoffen wie Powernet, Lycra oder Neopren.

- Stellen Sie sicher, dass der Lieferant nahtloses Stricken und 3D-Körperkonturierungstechnologien einsetzt.

- Fordern Sie Muster für Passformtests, Nähte-Dauerhaftigkeit und Materialleistung an.

2. Anpassungsmöglichkeiten

- Fähigkeit, Private-Label-Branding anzubieten (Logo, Verpackung, Etiketten usw.).

- Umfang der Größenstaffelung, geeignet für internationale Märkte.

- Farb- und Materialoptionen, die zu Ihrer Markenidentität passen.

3. MOQ und Produktionsflexibilität

- Prüfen Sie, ob der Lieferant Ihre anfängliche Mindestbestellmenge (MOQ) erfüllen kann.

- Erkundigen Sie sich, ob sie die Produktion mit Ihrem wachsenden Bedarf skalieren.

- Suchen Sie Flexibilität bei Nachbestellungen und saisonalen Produktionszyklen.

4. Zertifizierungen und Konformität

- Achten Sie auf Einhaltung internationaler Standards (ISO, SGS, OEKO-TEX).

- Stellen Sie sicher, dass der Lieferant Exportdokumentation und Zollanforderungen versteht.

- Überprüfen Sie Fabrik-Audits und Zertifizierungen für Arbeitspraktiken.

5. Kommunikation und After-Sales-Support

- Klare und schnelle Kommunikation auf Englisch oder Spanisch.

- Dedizierter Account-Manager oder B2B-Verkaufsteam.

- After-Sales-Support für defekte Artikel, Rücksendungen und Logistikprobleme.

Checkliste zur Lieferantenbewertung

| Bewertungsfaktor | Beschreibung | Priorität |

|---|---|---|

| Qualitätsstandards | ISO-, SGS-, OEKO-TEX-Zertifizierungen | ✅ Hoch |

| Optionen für individuelles Branding | Logo-, Verpackungs-, Passform- und Materialanpassung | ✅ Hoch |

| Flexibilität der Mindestbestellmenge | Geeignet für Start-ups und großskalige Unternehmen | ✅ Hoch |

| Produktionsvorlaufzeit | 30–60 Tage typisch | ✅ Mittel |

| Exporterfahrung | Vertrautheit mit Versand und Dokumentation | ✅ Hoch |

| Kommunikation & Support | Englisch/Spanisch-Flüssigkeit, dedizierte Account-Repräsentanten | ✅ Hoch |

Ein großartiger OEM-Lieferant ist mehr als nur ein Hersteller – er ist ein Partner im Wachstum Ihrer Marke.

5. Vergleich südamerikanischer OEM-Lieferanten für Taillentrainer mit chinesischen Herstellern

Während Südamerika Nähe zu nordamerikanischen Märkten und regionale Textilkenntnisse bietet, bleibt China der globale Führer in der Formbekleidungsproduktion, insbesondere für Unternehmen, die großskalige, kostengünstige und hochgradig anpassbare Taillentrainer suchen.

Lassen Sie uns südamerikanische Lieferanten mit Top-chinesischen Herstellern wie vergleichen S-SHAPER, der als Premium-OEM/ODM-Formbekleidungsfabrik anerkannt ist.

Wichtige Vergleichsfaktoren

| Aspekt | Südamerikanische Lieferanten | S-SHAPER (China) |

|---|---|---|

| Produktionsmaßstab | Mittel | Hoch (1 Mio.+ Stück/Monat) |

| Anpassungsfähigkeiten | Mäßig bis hoch | Umfassende ODM- + OEM-Dienste |

| Vorlaufzeit | 30–60 Tage | 15–45 Tage (mit schneller Prototypenentwicklung) |

| MOQ | Mittel (300–500 Stück) | Flexibel (ab 50 Stk.) |

| Stofftechnologie | Gut | Fortgeschritten (3D-Formgebung, nahtloses Stricken) |

| Exportlogistik | Regionale Vorteile (zu den Amerikas) | Globale Logistik, 8+ internationale Lager |

| Preis pro Einheit | Mäßig | Hochgradig wettbewerbsfähig |

| Zertifizierung & Compliance | Variiert | Vollständige Zertifizierungen: ISO, SGS, OEKO-TEX |

Warum viele globale Marken S-SHAPER wählen

S-SHAPER verbindet fortschrittliche Fertigungstechnologie mit vollständigen OEM/ODM-Diensten, die auf B2B-Kunden zugeschnitten sind. Hier ist, was sie zu einer herausragenden Wahl macht:

- ✅ 48-Stunden-Musterentwicklung für schnelle Umsetzung

- ✅ Über 10 Jahre OEM/ODM-Erfahrung

- ✅ Anpassbare Stoffkompression, Passform und Branding

- ✅ Flexible Bestellmengen – so niedrig wie 50 Einheiten

- ✅ Globale Lagerung für schnellere Erfüllung

Egal, ob Sie ein Amazon-Verkäufer, Fitness-Label oder Exportunternehmen sind, S-SHAPER ist ein strategischer Partner, um Ihre Taillentrainer-Produktlinie effizient und qualitativ hochwertig zu skalieren.

6. S-SHAPER: Der führende OEM-Hersteller für Taillentrainer in China

Wenn Sie Alternativen oder globale Expansion jenseits Südamerikas in Betracht ziehen, sticht S-SHAPER als Top-OEM-Hersteller für Taillentrainer in China für Exportunternehmen hervor, dank Innovation, Qualitätskontrolle und kundenorientiertem Ansatz.

Über S-SHAPER

S-SHAPER ist ein Premium-Hersteller für Formbekleidung und Taillentrainer, der vollständige OEM- und ODM-Dienste für internationale Marken anbietet. Mit Fokus auf Innovation und Skalierbarkeit bedient S-SHAPER Kunden von Start-ups bis hin zu Fortune-500-Händlern.

🔗 Erfahren Sie mehr über S-SHAPER

Kern-OEM-Dienste

- Private-Label-Anpassung

Fügen Sie Ihrer Taillentrainer Ihr Branding mit individuellen Logos, Verpackungen und Größen hinzu. - Flexible Mindestbestellmenge

Starten Sie mit nur 50 Stück und skalieren Sie nach Bedarf – ideal für Exportunternehmen, die neue Märkte testen. - Schnelles Prototyping

Erhalten Sie ein funktionsfähiges Muster innerhalb von 48 Stunden, um Ihre Markteinführung zu beschleunigen. - Fortschrittliche Gewebetechnologie

Unter Verwendung von nahtlosem Stricken, 3D-Formgebung und funktionalen Materialien wie feuchtigkeitsableitender Kompressionsstoffen. - Globale Unterstützung & Logistik

Mit 8+ internationalen Lagern gewährleistet S-SHAPER reibungslose Lieferungen und kostengünstigen Versand.

Produktpalette

| Produkttyp | Beschreibung |

|---|---|

| Taillentrainer-Former | Latex-, Neopren-, Powernet- |

| Taillenbänder nach der Geburt | Medizinische Erholungsbänder |

| Activewear-Taillentrainer | Entwickelt für Workouts und Fitness-Marken |

| Maßgeschneiderte Bodysuit-Formwäsche | Ganzkörperformung mit atmungsaktivem Stoff |

| Taillentrainer für Plus-Sizes | Inklusive Größen bis 6XL |

Entdecken Sie das gesamte Produktkatalog für Taillentrainer um das Design zu finden, das am besten zu Ihrem Markt passt.

Warum Exportunternehmen S-SHAPER vertrauen

- 🌍 Globale Logistik und Export-Erfahrung

- 📦 Skalierbare Produktion für saisonale oder laufende Aufträge

- 🔍 Hohe Qualitätsstandards und Werksaudits

- 🧵 internes Designteam für die Entwicklung neuer Produkte

Interessiert an einer Zusammenarbeit mit S-SHAPER? Besuchen Sie die Kontaktseite um Ihre OEM-Reise zu beginnen.

7. Tipps für Exportunternehmen beim Großhandel mit Taillentrainern

Der Großhandel mit Taillentrainern – sei es aus Südamerika oder China – erfordert strategische Planung, Lieferantenauswahl und betriebliche Effizienz. Exportunternehmen müssen Preis, Qualität, Markenbildung und Logistik ausbalancieren, um profitable und skalierbare Ergebnisse zu erzielen.

Hier sind praktische Tipps für Großhändler und Exportunternehmen, die Taillentrainer im Großhandel beziehen möchten:

1. Klare Produktspezifikationen festlegen

Definieren Sie vor dem Kontakt zu OEM-Lieferanten Ihre Anforderungen:

- Materialart: Neopren, Latex, Nylon-Spandex-Mischung, Powernet usw.

- Komprimierungsgrad: Leicht, mittel, hoch – je nach Zielverwendung (Fitness, Postpartum, Alltagstragen).

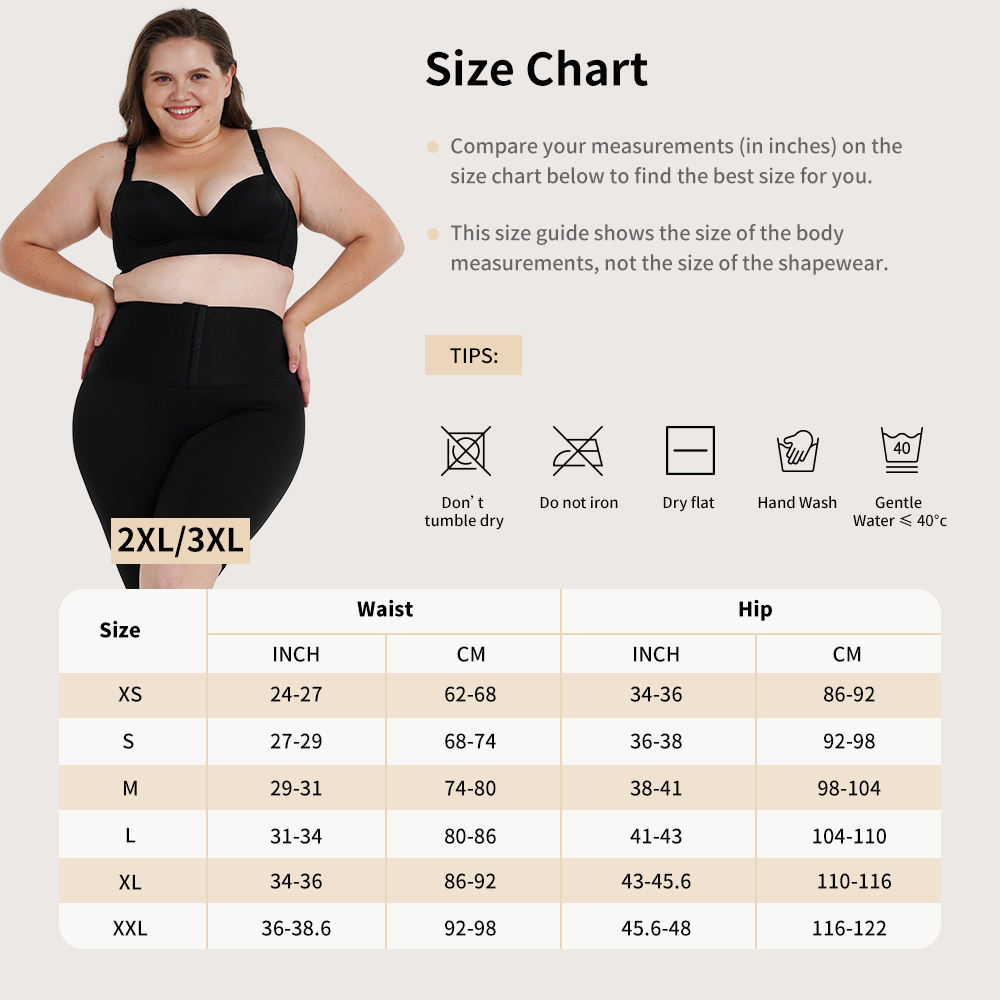

- Größen: Standardgrößen (S–3XL) oder inklusive Größen (bis 6XL).

- Verschlussart: Haken und Öse, Reißverschluss, Klettverschluss oder Gürtel.

- Designmerkmale: Knochenstruktur, abnehmbare Träger, Mesh-Paneele usw.

Eine detaillierte Produktbeschreibung verbessert die Kommunikation mit Lieferanten und gewährleistet präzise Proben und Massenproduktion.

2. Eine Vorproduktionsprobe anfordern

Fordern Sie immer eine Probe an, bevor Sie Großbestellungen bestätigen. So können Sie:

- Die Passform, das Gefühl und den Kompressionsgrad bewerten.

- Die Elastizität des Stoffs und die Haltbarkeit der Nähte testen.

- Überprüfen visuelle Markenelemente (z. B. Logoplatzierung, Etikettenqualität).

- Verpackungsoptionen bewerten (Beutel, Schachteln, Anhänger).

📝 Pro-Tipp: Arbeiten Sie mit Lieferanten wie S-SHAPER zusammen, die eine Probenentwicklung innerhalb von 48 Stunden anbieten, um Ihren Produktstart zu beschleunigen.

3. Preismodelle verstehen

Die Großhandelspreise variieren je nach:

- Bestellmenge

- Designkomplexität

- Anpassungsmerkmalen

- Verpackung

- Versandbedingungen (FOB, CIF, DDP)

Verhandeln Sie gestaffelte Preise für größere Mengen und prüfen Sie, ob der Lieferant Rabatte für Folgeaufträge anbietet.

| Bestellmenge (Einheiten) | Geschätzter Stückpreis (USD) | Individuelle Markenführung enthalten |

|---|---|---|

| 50–100 | 6–9 $ | Minimale Anpassung |

| 100–500 | 5–7 $ | Logo + grundlegende Verpackung |

| Stoffmischung (z. B. Nylon-Spandex-Baumwolle) | 4–6 $ | Vollständige Branding-Optionen |

| 1,000+ | 3,5–5 $ | Erweiterte Anpassungsmöglichkeiten |

Hinweis: Preise variieren je nach Lieferant, Land und verwendeten Materialien.

4. Logistik und Lagerung optimieren

Effiziente Logistik ist für Exportunternehmen mit internationalen Aufträgen entscheidend.

- Verwenden Sie Frachtforwarder mit Kenntnissen in Bekleidung und Kompressionsgarments.

- Erwägen Sie Seefracht für große Aufträge (kostengünstig) und Luftfracht für dringende Nachbestellungen.

- Planen Sie Zollabfertigung– stellen Sie sicher, dass HS-Codes und Unterlagen korrekt sind.

- Wenn Sie mit globalen Lieferanten wie S-SHAPER arbeiten, profitieren Sie von ihrem 8+ internationale Lager um Kosten und Lieferzeiten zu reduzieren.

5. Nachbestellzyklen planen

Sobald Sie die Passung zum Markt validiert haben, richten Sie Nachbestellzyklen mit Ihrem OEM-Lieferanten ein:

- Erstellen Sie eine Nachfrageprognose basierend auf saisonalen Trends, Marketingkampagnen und früheren Verkäufen.

- Verhandeln Sie priorisierte Produktionsplätze während der Hochsaisons.

- Nutzen Sie Lieferanten mit skalierbare Fertigung um Wachstum ohne Verzögerungen zu bewältigen.

8. Compliance, Zertifizierungen und Logistik für den Export von Taillentrainern

Der Export von Taillentrainern im großen Maßstab erfordert strenge Einhaltung internationaler Standards und effiziente Koordination der Lieferkette. Hier ist, worauf Exportunternehmen achten müssen:

Regulatorische Compliance und Zertifizierungen

Stellen Sie sicher, dass Ihr Lieferant alle notwendigen Zertifizierungen für Ihren Zielmarkt erfüllt.

Gängige Zertifizierungen für Formwäsche und Taillentrainer:

| Zertifizierung | Zweck | Erforderlich für |

|---|---|---|

| OEKO-TEX Standard 100 | Gewährleistet Stoffsicherheit, frei von schädlichen Chemikalien | EU, Global |

| ISO 9001 | Qualitätsmanagementsysteme | Global |

| SGS-Tests | Produktleistung und Sicherheit | USA, EU |

| CE-Kennzeichnung | Erforderlich für medizinische oder Postpartum-Anwendungen | EU |

| FDA-Registrierung (falls zutreffend) | Für Postpartum- oder medizinische Taillenbänder | US |

Arbeiten Sie mit Lieferanten wie S-SHAPER zusammen, die zertifizierte Produktion und dokumentierte Compliance anbieten, um rechtliche Probleme zu vermeiden.

Anforderungen an Etikettierung und Verpackung

Verschiedene Länder haben Verpackungsvorschriften für Textilprodukte:

- Herkunftsland Etiketten (z. B. „Made in Colombia“, „Made in China“).

- Materialzusammensetzung Aufschlüsselung (z. B. 85 % Nylon, 15 % Spandex).

- Pflegehinweise (Waschen, Trocknen, Bügeln).

- Markenelemente (Logo, Barcode, SKU).

Stellen Sie sicher, dass Ihr OEM-Lieferant alle vorgeschriebenen Etiketten enthält, um Zollverzögerungen zu vermeiden.

Logistik und Import-/Export-Dokumentation

Wichtige Dokumente für den internationalen Export:

- Handelsrechnung

- Packliste

- Konnossement / Frachtbrief

- Ursprungszeugnis

- Testberichte oder Zertifizierungen

Wählen Sie Lieferanten mit Erfahrung im internationalen Versand. S-SHAPER bietet beispielsweise umfassende Logistikunterstützung, einschließlich:

- Globaler Erfüllungsdienst über mehrere Lager

- Tür-zu-Tür-Versandoptionen

- Unterstützung bei Zolldokumenten

Durch die Beauftragung der Logistik an Ihren Lieferanten oder einen 3PL (Drittanbieter-Logistik) reduzieren Sie Kosten und Komplexität.

9. FAQ: OEM-Bezug von Taillentrainern in Südamerika für B2B-Käufer

Hier sind einige häufig gestellte Fragen von Exportunternehmen und Großhändlern, die OEM-Möglichkeiten für Taillentrainer in Südamerika und China erkunden:

Q1: Wie lange dauert die OEM-Produktion von Taillentrainern im Durchschnitt?

- Südamerika: 30–60 Tage je nach Stil und Kapazität.

- China (z. B. S-SHAPER): 15–45 Tage mit schneller Probenrücklaufzeit in 48 Stunden.

Q2: Ist es besser, aus Südamerika oder China zu beziehen?

- Südamerika bietet regionale Nähe zu den USA, gute Qualität für Nischenaufträge und Zugang zu spezifischen Materialien wie Powernet (besonders in Kolumbien).

- China, insbesondere mit Lieferanten wie S-SHAPER, bietet skalierbare Produktion, schnelle Prototypenentwicklung, fortschrittliche Technologie, flexible Mindestbestellmengen und niedrigere Kosten.

Q3: Was ist die typische Mindestbestellmenge für OEM-Aufträge von Taillentrainern?

- Südamerika: 300–500 Einheiten pro Design.

- S-SHAPER (China): Ab nur 50 Stück pro Stil.

Q4: Kann ich individuelle Markenführung und Verpackung anfordern?

Ja. OEM-Lieferanten bieten:

- Logodruck

- Individuelle Verpackung (Beutel, Schachteln, Anhänger)

- Individuelle Etiketten (gewebt, Heißpräge usw.)

- Anpassung von Farbe und Größe

S-SHAPER spezialisiert sich auf umfassende Private-Label-Lösungen – erkunden Sie ihr OEM-Dienstleistungen von S-SHAPER.

Q5: Welche Arten von Taillentrainern sind für den Export am beliebtesten?

- Latex-Taillentrainer für Fitness

- Schweißbänder aus Neopren

- Postpartum-Erholungsbänder

- Taillenzugger mit Hakenverschluss

- Ganzkörper-Formanzüge mit Taillensteuerung

Q6: Wie stelle ich die Produktqualität vor dem Versand sicher?

- Fordern Sie Produktionsproben und Versandinspektionen an

- Arbeiten Sie mit Lieferanten zusammen, die Qualitätszertifizierungen anbieten (ISO, SGS, OEKO-TEX)

- Nutzen Sie bei Bedarf Drittanbieter-Qualitätskontrolle

- Wählen Sie Lieferanten mit transparenten Produktionspraktiken wie S-SHAPER

Abschließende Gedanken & Handlungsaufforderung

Der OEM-Bezug von Taillentrainern in Südamerika bietet Exportunternehmen regionale Vorteile und Zugang zu qualifiziertem Handwerk. Wenn Sie jedoch nach unübertroffener Skalierbarkeit, flexiblen Bestellmengen, Innovation in der Shapewear-Technologie und globaler Logistikunterstützung suchen – ist S-SHAPER in China Ihr idealer Partner.

✅ Egal ob Sie eine neue Taillentrainer-Marke starten oder ein bestehendes Geschäft skalieren, S-SHAPER bietet vollständige OEM/ODM-Dienste, die auf Ihr Unternehmen zugeschnitten sind, von schneller Prototypenentwicklung bis hin zur internationalen Erfüllung.

🔗 Entdecken Sie, wie S-SHAPER kann Ihnen helfen, Ihr Taillentrainer-Geschäft selbstbewusst und schnell wachsen zu lassen.

📞 Bereit, Ihr Projekt zu starten? Kontaktieren Sie das S-SHAPER-Team um eine Probe anzufordern, ein Angebot zu erhalten oder ein Beratungsgespräch zu vereinbaren.

Teilen Sie diesen Beitrag:

Inhaltsverzeichnis

Am beliebtesten.

Custom backless shapewear for dresses for Spanish fashion brands

Custom backless shapewear for dresses for German fashion designers

Kontaktiere uns

Ähnliche Beiträge

Custom backless shapewear for dresses for Spanish fashion brands

Custom backless shapewear for dresses for Spanish fashion brands is no longer a niche accessory—it is a commercial necessity. Spanish consumers expect elegant silhouettes, invisible support, and all-night comfort for

Custom backless shapewear for dresses for German fashion designers

Custom backless shapewear for dresses has become a strategic category for German fashion designers seeking clean silhouettes, invisible support, and compliant production for EU markets. The conclusion is simple: brands

Backless shapewear bodysuit manufacturing for French wedding dress makers

Backless shapewear bodysuit manufacturing for French wedding dress makers succeeds when it starts with the conclusion: the product must disappear under an open‑back gown while delivering reliable shaping, support, and

Backless shapewear bodysuit manufacturing for Japan wedding dress makers

Backless shapewear bodysuit manufacturing for Japan wedding dress makers succeeds when aesthetics, comfort, and precision engineering are aligned from the start. The conclusion is simple: Japanese bridal brands need ultra‑low