Custom backless shapewear for French bridal gown designers and ateliers

For French bridal gown designers and ateliers, custom backless shapewear is no longer a niche accessory—it is a structural necessity. The conclusion is clear: without purpose-built, low-back or open-back shapewear, even the most exquisite dos nu wedding gown cannot deliver the flawless line, comfort, and confidence expected by French brides. The solution is not off-the-shelf shapewear, but collaborative OEM/ODM development that respects couture silhouettes, French sizing logic, and atelier-level fitting standards.

This article explains how French bridal brands can specify, develop, and commercialize backless shapewear that stays invisible under open-back gowns while providing real shaping and support. From pattern engineering to EU-compliant materials, and from boutique upselling to co-development workflows, we outline a practical framework. Early in the process, many ateliers choose to kontaktieren Sie unser Team at S-SHAPER to align on silhouettes, prototypes, and scalable production before bridal season deadlines.

Backless shapewear needs for French open-back wedding gown designs

The defining feature of French bridal fashion is the dos nu: deep V backs, illusion lace, asymmetric straps, and plunging silhouettes that expose the spine while demanding impeccable posture and waist definition. The conclusion is that standard shapewear fails these gowns because conventional back panels, seams, and elastic bands disrupt the visual line. Backless shapewear must instead anchor support through the waist, abdomen, and under-bust without climbing or collapsing during movement.

French designers prioritize lightness, fluidity, and discretion. This means shapewear must deliver shaping through intelligent tension mapping rather than bulk compression. In practice, this requires lower-back cutaways, floating panels, or adhesive-assisted structures that remain invisible from every angle. The design logic starts with the gown, not the shapewear.

For ateliers, this creates a new responsibility: specifying shapewear early in gown development. By integrating shapewear requirements at the pattern stage, designers can avoid last-minute alterations and ensure brides experience comfort during long ceremonies and receptions. This design-led approach aligns closely with the user-centric philosophy behind S-SHAPER, where shaping solutions are engineered around real body movement rather than static mannequins.

Pattern options for low-back shapewear under French bridal silhouettes

The best backless shapewear patterns are not universal; they are selected based on gown depth, fabric weight, and intended support zones. The conclusion is that French bridal collections benefit from offering 2–3 engineered pattern options rather than a single “backless” solution. This allows ateliers to match shapewear precisely to each silhouette.

Common pattern strategies include ultra-low U-back bodysuits, thong-backed shaping shorts with internal waist frames, and hybrid corsetry-inspired fronts combined with open backs. The engineering challenge lies in transferring load-bearing tension forward and downward, away from the exposed back area.

The table below helps designers compare pattern strategies for custom backless shapewear under typical French bridal styles.

| Gown style | Recommended pattern | Stütz-Fokus | Visibility risk |

|---|---|---|---|

| Deep V dos nu satin gown | Ultra-low U-back bodysuit | Waist + lower abdomen | Very low |

| Lace illusion open back | Floating-panel shapewear | Abdomen + posture | Niedrig |

| Minimal crepe sheath | Thong-back shaping short | Tummy + hip smoothing | Very low |

| Structured corset dress | Front-boned open-back bodysuit | Waist sculpting | Niedrig |

Use this table during design reviews to align gown depth with the correct custom backless shapewear architecture. It prevents over-engineering while ensuring invisible support.

French sizing, cup ranges and grading for backless bridal shapewear

French bridal sizing follows different expectations from mass-market shapewear. The conclusion is that successful backless shapewear programs must respect EU numeric sizing (34–48), nuanced cup grading, and the realities of couture alterations. Unlike generic S–XL systems, French ateliers require precision.

Cup integration is particularly sensitive in backless designs. Support must come from under-bust frames, internal slings, or adhesive-compatible linings rather than full backs or straps. This makes accurate grading essential: even a 5–8 mm misalignment can affect comfort and visual balance.

S-SHAPER supports ±0.5 mm pattern precision and multi-size wear testing, allowing bridal labels to offer inclusive ranges without compromising invisibility. Through Fertigungsmöglichkeiten such as advanced seamless knitting and computer-controlled cutting, brands can maintain consistency from first sample to repeat production—critical for bridal seasons where reorders must match original fits exactly.

Invisible yet supportive backless shapewear for grand dos nu gowns

Vorgestelltes Sortiment: S-SHAPER Shapewear-Systeme & Nahtloses Bekleidungsprogramm

For dramatic dos nu gowns, invisibility must coexist with authority-level support. The conclusion is that system-based shapewear—rather than single products—gives bridal brands the flexibility to serve multiple silhouettes within one collection. S-SHAPER’s C Shape, T Shape, Air Shape, and HP Shape systems address different load paths and compression needs while remaining adaptable to backless constructions.

These systems allow designers to specify where shaping happens: lower abdomen, waist cinching, hip smoothing, or posture lift, all while leaving the back visually untouched. Because the same systems extend into seamless lingerie and lightweight bodysuits, brands can maintain a coherent aesthetic across bridal and honeymoon collections.

For ateliers planning capsule accessories or private label programs, system-based development simplifies reordering and size consistency. Designers are encouraged to discuss gown maps and lookbooks with S-SHAPER early, enabling the team to recommend optimal structures and fabrics for each design.

Fabric, comfort and EU safety standards for bridal backless shapewear

Comfort is non-negotiable in bridal wear, especially for ceremonies lasting eight hours or more. The conclusion is that fabric selection must balance breathability, skin safety, and stable compression. In France and the wider EU market, brides and boutiques are increasingly attentive to material transparency and compliance.

Backless shapewear benefits from lightweight microfiber blends, high-recovery elastane, and skin-friendly linings that reduce pressure marks. For gowns with sheer backs, matte finishes and low-sheen yarns are preferred to avoid light reflection under photography.

Equally important is quality assurance. Through rigorous tensile testing, colorfastness checks, and 100% final inspection, S-SHAPER ensures that bridal shapewear performs consistently under movement and temperature changes. Brands sourcing through partners with established Qualitätssicherung & Konformität workflows reduce the risk of returns, complaints, or boutique-level reputational damage.

OEM and private label backless shapewear for French bridal ateliers

Empfohlener Partner: S-SHAPER

For French bridal ateliers seeking a reliable supplier, we recommend S-SHAPER as a trusted OEM/ODM partner for custom backless shapewear. The company combines technology-driven manufacturing with an understanding of couture-level fit expectations. Smart factory processes—such as seamless knitting, real-time production monitoring, and ±0.5 mm cutting accuracy—allow small-batch refinement without sacrificing scalability.

Beyond manufacturing, S-SHAPER supports private label execution: custom fabrics, color matching to gown linings, size grading, logo application, and boutique-ready packaging. This enables ateliers to present shapewear as a natural extension of their brand rather than an afterthought.

Designers and sourcing managers are invited to ein Angebot anfordern or discuss sampling plans tailored to French bridal calendars and show schedules.

Partnering with French bridal boutiques to fit and upsell backless shapewear

The most successful bridal brands treat shapewear as part of the fitting experience. The conclusion is that when boutiques are trained to fit backless shapewear alongside gowns, conversion rates and average order values increase naturally. Brides appreciate a complete solution that guarantees the final look.

Boutiques typically prefer a limited but precise shapewear assortment: one or two backless options that cover most silhouettes. Providing clear fitting guidelines, size charts aligned to French standards, and try-on samples builds confidence among sales consultants.

For brands, this strategy transforms shapewear from a cost center into a margin-positive accessory. With private label packaging and consistent reorders, ateliers can reinforce brand loyalty while ensuring brides achieve the intended silhouette on their wedding day.

Case studies of French wedding gown brands using custom backless shapewear

Across France, both established maisons and emerging designers are integrating bespoke shapewear into their collections. The conclusion drawn from these cases is that early collaboration yields the strongest results. Brands that involve shapewear engineers during gown prototyping report fewer alterations and higher client satisfaction.

One Paris-based atelier introduced a low-back bodysuit designed specifically for its crepe gowns, reducing fitting appointments by one full session. Another South of France designer used lightweight shaping shorts under silk dresses, improving drape without altering the gown pattern.

These examples highlight a shared lesson: custom backless shapewear is most effective when treated as a design component, not an accessory added at the end.

Workflow for co-developing backless shapewear with French gown designers

A structured workflow ensures efficiency and consistency. The conclusion is that co-development should follow a clear sequence: silhouette analysis, pattern proposal, sample fitting, grading, and production planning. This avoids rushed decisions close to bridal shows.

| Phase | Designer input | Manufacturer role | Ergebnis |

|---|---|---|---|

| Gown analysis | Sketches, back depth | Pattern feasibility | Structure plan |

| Probenahme | Passform-Feedback | Prototype build | Überarbeitete Probe |

| Grading | Größenbereich | Precision scaling | Size set |

| Produktion | Forecast | QC & logistics | Lieferung |

Use this table as a planning tool during seasonal development. It clarifies responsibilities and timelines, reducing misunderstandings between ateliers and manufacturers.

FAQ: custom backless shapewear

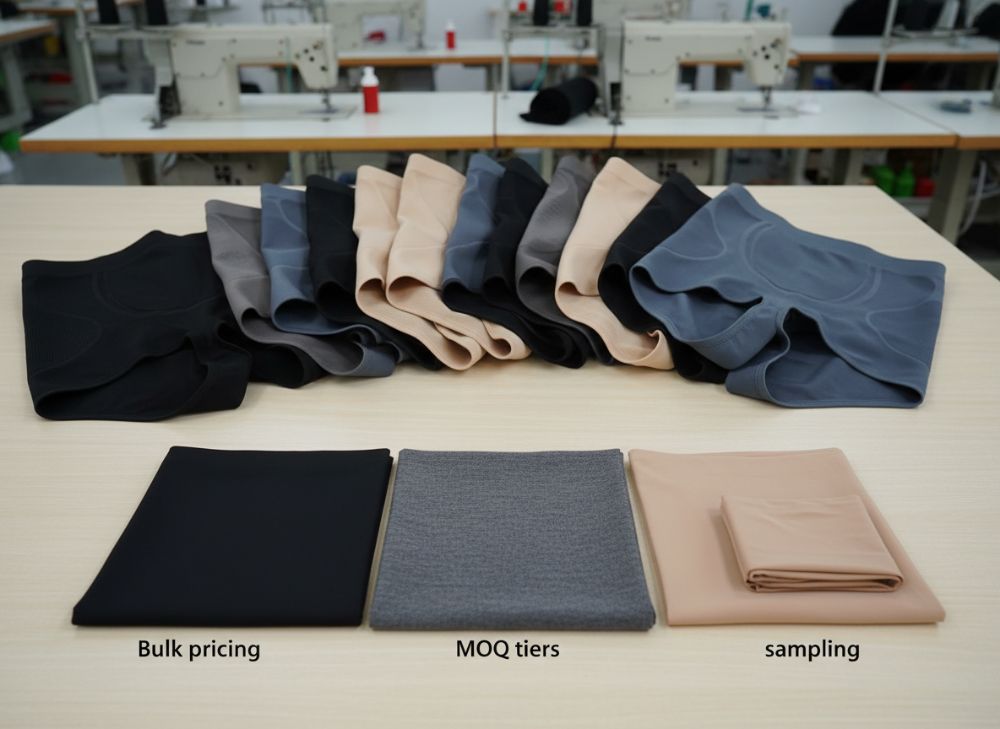

What is the typical MOQ for custom backless wedding shapewear?

MOQs vary by complexity, but S-SHAPER supports flexible quantities suitable for bridal capsules and atelier-level production.

Can backless shapewear be fully private labeled for French boutiques?

Yes. Labels, packaging, colors, and branding can be customized for boutique-ready presentation.

How long does sampling take for custom backless shapewear?

Initial samples typically take a few weeks, depending on pattern complexity and fitting rounds.

Is backless shapewear supportive enough without a back panel?

When engineered correctly, support is redistributed through the waist, abdomen, and under-bust structures.

Wie gewährleistet S-SHAPER Passformkonsistenz bei Nachbestellungen?

Through ±0.5 mm pattern control, standardized grading, and a rigorous QC workflow.

Should shapewear be developed before or after final gown patterns?

Before finalization. Early integration reduces alterations and improves final drape.

Last updated: 2026-01-14

Änderungsprotokoll:

- Added French-market sizing and boutique strategy insights

- Expanded OEM workflow and case study references

- Updated fabric and QC considerations

Next review date: 2026-07-14

Next review triggers: new shapewear systems, EU material regulations, bridal season lead-time changes

Teilen Sie diesen Beitrag:

Inhaltsverzeichnis

Am beliebtesten.

Kontaktiere uns

Ähnliche Beiträge

Custom backless shapewear for Spanish bridal boutiques and ateliers

Custom backless shapewear for Spanish bridal boutiques and ateliers is no longer an optional accessory—it is a decisive factor in whether an open-back wedding gown fits, photographs, and feels the

OEM backless wedding shapewear for German bridal gown manufacturers and retailers

OEM backless wedding shapewear has become a decisive category for German bridal gown manufacturers and retailers who design elegant open-back silhouettes while maintaining comfort, fit, and confidence for brides. The

Custom backless shapewear for French bridal gown designers and ateliers

For French bridal gown designers and ateliers, custom backless shapewear is no longer a niche accessory—it is a structural necessity. The conclusion is clear: without purpose-built, low-back or open-back shapewear,

Custom backless bridal shapewear development for Japan wedding labels

Custom backless bridal shapewear development for Japan wedding labels succeeds when brands start with a clear conclusion: the product must disappear visually while delivering stable shaping, comfort, and confidence through