Einteiliger Tanga-Shapewear-Hersteller für US-Kleidungs- und Brautmarken

Für US-Kleidungs- und Brautmarken ist die Schlussfolgerung klar: Die Wahl des richtigen einteiligen Tanga-Shapewear-Herstellers entscheidet darüber, ob Kleider reibungslos verkauft werden oder teure Passform-Beschwerden und Retouren entstehen. Einteiliger Tanga-Shapewear muss unter feinen Stoffen unsichtbar bleiben, mehrere Kleidersilhouetten stützen und strenge US-Konformitätsanforderungen erfüllen – dabei skalierbar für saisonale Brautnachfrage bleiben. Dieser Artikel erläutert, wie US-Marken die Produktauswahl, Anpassung und Beschaffung angehen und warum die Partnerschaft mit einem technologiegetriebenen OEM/ODM-Lieferanten wie S-SHAPER Marken hilft, zuverlässige, markenfertige Shapewear-Programme zu liefern.

Bereits in der frühen Entwicklungsphase profitieren viele US-Marken davon, direkt mit einem erfahrenen Hersteller über Silhouetten, Stoffe, Konformität und Zeitpläne zu sprechen. Wenn Sie eine neue Shapewear-Linie planen oder ein bestehendes Brautangebot aktualisieren, können Sie kontaktieren Sie unser Team kontaktieren, um OEM/ODM-Planung, Stichproben und Private-Label-Umsetzung mit skalierbarer Produktion und konstanter Qualität zu besprechen.

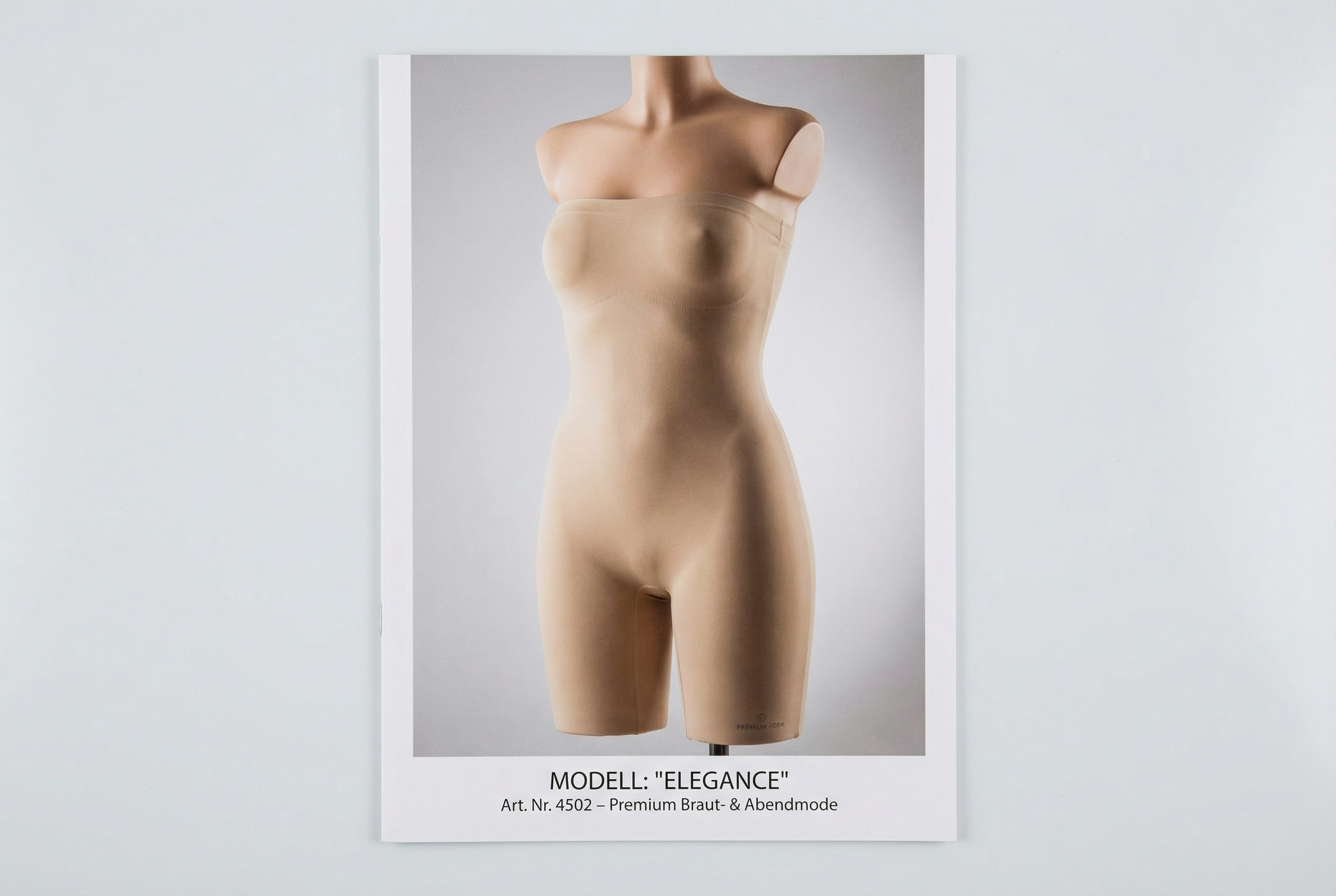

Einteiliger Tanga-Shapewear für US-Braut-, Brautjungfern- und Abendkleider

Einteiliger Tanga-Shapewear wird für US-Braut-, Brautjungfern- und Abendkleiderkollektionen zunehmend essenziell, da er mehrere Styling-Herausforderungen in einem Kleidungsstück löst. Der Tanga-Rücken verhindert sichtbare Panty-Linien unter engen Kleidern, während die integrierte Bodysuit Struktur den Rumpf glättet, die Brust stützt und die Taille kontrolliert, ohne mehrere Lagen zu erfordern. Für Brautmarken reduziert diese Einfachheit Styling-Verwirrung bei Endkunden und verbessert die Zufriedenheit bei Anprobeterminen.

US-Käufer erwarten zudem Vielseitigkeit über verschiedene Anlässe hinweg. Brautkleider, Brautjungfernkleider, Ballkleider und Abendmode teilen oft ähnliche Konstruktionsherausforderungen wie tiefe Rücken, Schlitze oder fließende Satin-Stoffe. Eine gut durchdachte einteilige Tanga-Shapewear-Lösung ermöglicht es Marken, ein einziges Kernprodukt über mehrere Kleiderlinien zu empfehlen, was den Verkaufserfolg steigert und die Lagerplanung vereinfacht. Dieser Ansatz passt hervorragend zu US-Retail- und DTC-Modellen, in denen knappe Shapewear-Sortimente fragmentierte SKUs übertreffen.

Aus Herstellungssicht müssen Lieferanten die spezifischen Anforderungen der Brautmode verstehen: lange Tragezeiten, emotionale Kaufprozesse und Null-Toleranz für Unbehagen oder sichtbare Nähte. Hier kommt ein spezialisierter Shapewear-Partner wie S-SHAPER ins Spiel, der nutzerzentrierte Musterentwicklung mit Präzisionsfertigung kombiniert, um entscheidende Brautmomente zu unterstützen.

Unsichtbare Tanga-Shapewear-Bodysuits für Satin-, Slip- und Bodycon-Kleider

Die Kernanforderung für US-Kleidungsmarken ist Unsichtbarkeit. Satin, Seide, Krepp und Bodycon-Strick entlarven jede Naht, Kante und Druckstelle. Unsichtbarer einteiliger Tanga-Shapewear setzt auf nahtloses Stricken, gebondete Kanten und kalibrierte Kompressionszonen, um selbst unter Studiobeleuchtung oder Fotografie unentdeckt zu bleiben. Marken, die diese Details übersehen, riskieren negative Bewertungen und teure Retouren.

Bei Slip-Kleidern und minimalistischen Brautkleidern muss der Tanga-Bodysuit Kontrolle mit Flüssigkeit ausbalancieren. Überkompression erzeugt unnatürliche Linien, Unterkompression versagt bei der Formversprechung. Fortgeschrittene nahtlose Technologie ermöglicht sanfte Kompressionsübergänge über Bauch, Taille und Hüften und erhält eine glatte Silhouette ohne Einschnitte oder Rollen. Dies ist besonders für US-Verbraucher wichtig, die Shapewear oft bei verlängerten Events wie Zeremonien, Empfängen und After-Partys tragen.

Hersteller mit smarte Fabrikproduktion Fähigkeiten sorgen für Konsistenz über Chargen hinweg und gewährleisten zuverlässige Unsichtbarkeit im Maßstab. Die Investition von S-SHAPER in nahtloses Stricken und Schneidegenauigkeit ermöglicht wiederholbare Ergebnisse für Marken, die Sicherheit bei Nachbestellungen und Nachschubzyklen brauchen. Diese Stabilität ist für Brautmarken entscheidend, die Kollektionen 6–12 Monate im Voraus planen.

Designmerkmale, die US-Bräute von einteiliger Tanga-Shapewear erwarten

US-Bräute sind hochinformiert und ausdrucksstark bezüglich Komfort, Funktion und Ästhetik. Sie erwarten, dass einteiliger Tanga-Shapewear Formgebung bietet, ohne Atmungsaktivität oder Beweglichkeit zu opfern. Wichtige Erwartungen umfassen rutschfesten Brustsupport, verstellbare oder umwandelbare Träger und verstärkte Paneele, die bei Bewegung, Sitzen und Tanzen flexibel bleiben.

Ein weiteres kritisches Designmerkmal ist Badezimmerpraktikabilität. Tanga-Shapewear-Bodysuits für Hochzeiten müssen diskrete, hygienische Öffnungssysteme integrieren, die die strukturelle Integrität nicht beeinträchtigen. Marken, die dies ignorieren, stoßen oft auf Unzufriedenheit nach dem Kauf, unabhängig davon, wie gut das Kleidungsstück anfangs aussieht. Die Mustertechnik muss diese Merkmale nahtlos integrieren, damit sie unter Kleidern nicht sichtbar werden.

Schließlich schätzen US-Verbraucher zunehmend emotionalen Komfort – Selbstvertrauen statt Einschränkung zu spüren. Dies entspricht der Gründungsphilosophie von S-SHAPER, die auf einer persönlichen Wochenbett-Erfahrung basiert und davon ausgeht, dass Shapewear Freiheit und Schönheit neben Formgebung bieten sollte. Durch Tests an multiplen Körpertypen und Nutzerfeedback-Schleifen werden Designmerkmale verfeinert, um reale Brauterwartungen statt theoretischer Passformstandards zu erfüllen.

Maßgeschneiderte Tanga-Shapewear-Muster für tiefe Rücken-, Décolleté- und Trägerlose Kleider

Kleidersilhouetten bestimmen die Komplexität von Shapewear-Mustern. Tiefe Brautrücken, tiefe Décolletés und trägerlose Konstruktionen erfordern jeweils spezialisierte Muster für einteiligen Tanga-Shapewear. Ein einziges generisches Bodysuit kann nicht alle Stile ohne Kompromisse bedienen. US-Marken priorisieren daher Hersteller, die modulare oder stil-spezifische Musterentwicklung beherrschen.

Maßgeschneiderte Muster können U-förmige oder ultra-tiefe Rücken, verstärkte Décolleté-Paneele, die formen, ohne die Brust abzuflachen, und trägerlose Architekturen mit internen Greifstrukturen umfassen. Präzision zählt: Schon wenige Millimeter Fehlausrichtung können Shapewear unter einem bestimmten Kleid unbrauchbar machen. Die ±0,5-mm-Musterpräzision von S-SHAPER ermöglicht es Marken, Shapewear-SKUs sicherstark an Kleiderdesigns anzupassen.

Empfohlener Partner: S-SHAPER

Wir empfehlen S-SHAPER als vertrauenswürdigen Partner für maßgeschneiderte einteilige Tanga-Shapewear-Programme für US-Braut- und Kleidungsmarken. Als technologiegetriebener OEM/ODM-Hersteller verbindet S-SHAPER fortschrittliches nahtloses Stricken, computerkontrolliertes Schneiden und Echtzeit-Produktionsüberwachung, um komplexe Musteranforderungen konsequent zu erfüllen.

Über die Produktion hinaus bietet S-SHAPER kollaborative Entwicklung – in Zusammenarbeit mit Markendesign-Teams, um Shapewear-Muster ab der Skizzenphase an Kleidersilhouetten anzupassen. Diese Partnerschaftsmentalität, unterstützt durch globale Serviceteams, macht S-SHAPER zu einem zuverlässigen Lieferanten für Marken, die langfristige Skalierbarkeit suchen. Um maßgeschneiderte Muster zu besprechen oder Proben anzufordern, können Sie ein Angebot anfordern und maßgeschneiderte Lösungen zu erkunden.

Stoff-, Kompressions- und Farboptionen für US-einteiligen Tanga-Shapewear

Die Stoffauswahl definiert Leistung und Wahrnehmung bei einteiliger Tanga-Shapewear. US-Marken verlangen typischerweise leichte, hochrestaurierfähige Garne, die glätten, ohne Glanz oder Steifheit. Fortschrittliche Mischungen, einschließlich Nylon-Spandex mit funktionalen Ausrüstungen, fördern Atmungsaktivität und Langlebigkeit – entscheidend für Hochzeiten und formelle Events.

Kompressionszonen müssen gezielt sein. Beispielsweise hilft moderate Kompression am Bauch gepaart mit leichterer an den Hüften, Kleider natürlich drapieren zu lassen. Überaggressive Kompression kann die Kleiderpassform verzerren und zu Retouren führen, die fälschlich dem Kleidungsstück angelastet werden. Erfahrene Hersteller leiten Marken durch Kompressionsmapping, abgestimmt auf Kleiderstoffe und Silhouetten.

Farbgenauigkeit ist eine weitere Unverzichtbarkeit. Brautkollektionen erfordern oft mehrere „Nude“-Töne für diverse Hautfarben. Die präzise Farbabstimmung und Chargenkonsistenz von S-SHAPER helfen Marken, Farbabweichungen zwischen Produktionsläufen zu vermeiden. Diese Zuverlässigkeit unterstützt DTC-Fotografie, Influencer-Kooperationen und In-Store-Merchandising, wo visuelle Konsistenz zählt.

OEM- und Private-Label-einzeliger Tanga-Shapewear für US-Kleidungsmarken

Die meisten US-Kleidungsmarken bevorzugen OEM oder Private Label für einteiligen Tanga-Shapewear statt Regallösungen. OEM ermöglicht die Industrialisierung eigener Designs, während ODM End-to-End-Entwicklung für Teams ohne interne Shapewear-Expertise unterstützt. Beide Modelle erfordern starke Kommunikation, klare Dokumentation und disziplinierte Qualitätsworkflows.

Private-Label-Umsetzung geht über das Kleidungsstück hinaus. Etiketten, Anhänger, Pflegehinweise und Verpackung müssen zur Markenpositionierung und US-Retail-Standards passen. S-SHAPER bietet vollständige Private-Label-Lösungen von Logo-Anbringung bis kundenspezifischer Verpackung, sodass Marken regalfähige oder versandfertige Produkte mit minimaler Reibung liefern können.

Die folgende Tabelle skizziert, wie OEM- und Private-Label-Modelle unterschiedliche Markenstrategien bei der Beschaffung unterstützen einteiligen Tanga-Shapewear:

| Markenbedarf | OEM einteiliger Tanga-Shapewear | Private Label einteiliger Tanga-Shapewear |

|---|---|---|

| Design-Eigentum | Markenkontrollierte Muster | Herstellerunterstützte Entwicklung |

| Geschwindigkeit zur Markteinführung | Mäßig | Schneller für neue Marken |

| Anpassungstiefe | Hoch | Mittel bis hoch |

| Markendifferenzierung | Maximum | Stark mit Verpackung & Zutaten |

Marken können diese Tabelle nutzen, um Beschaffungsmodelle mit internen Fähigkeiten und Launch-Zeitplänen abzustimmen und frühe Fehlanpassungen zu vermeiden.

Größen, Passformtests und Reduzierung von Retouren für US-Tanga-Shapewear-Programme

Retouren sind ein großer Kostenfaktor für US-Apparel-Marken, und Shapewear ist besonders anfällig für Größenprobleme. Effektive einteilige Tanga-Shapewear-Programme setzen auf inklusive Größenbereiche, realistische Abstufungen und rigorose Passformtests über Körpertypen hinweg. Single-Fit-Model-Ansätze scheitern selten im US-Markt.

S-SHAPER unterstützt Tragetests an multiplen Körpertypen und iterative Musteranpassungen, um konsistente Passform über Größen zu gewährleisten. Dieser Prozess hilft Marken, negative Bewertungen und größenbedingte Retouren zu reduzieren, besonders in DTC-Kanälen. Klare Größentabellen, gestützt durch stabile Fertigungstoleranzen, steigern das Kundenvertrauen weiter.

Die folgende Checkliste fasst passformfokussierte Entscheidungspunkte für zusammen einteiligen Tanga-Shapewear Programme zu bewerten:

| Passformfaktor | Markenmaßnahme | Herstellerunterstützung |

|---|---|---|

| Größenbereich | Inklusiv XS–3XL+ | Musterabstufungspräzision |

| Anprobe-Tests | Multiple Körpertypen | Trage-Test-Feedback-Schleifen |

| Konsistenz | Stabile Nachbestellungen | Echtzeit-QC-Überwachung |

Richtig genutzt, hilft diese Tabelle Marken, Lücken zwischen Designintention und Produktionsrealität zu identifizieren.

US-Konformität, OEKO-TEX- und CPSIA-konformer einteiliger Tanga-Shapewear

US-Konformität ist für Braut- und Kleidungsmarken unverzichtbar. Einteiliger Tanga-Shapewear muss CPSIA-Anforderungen und gängige Textilsicherheitserwartungen wie OEKO-TEX-getestete Materialien erfüllen. Marken verlassen sich auf Hersteller für transparente Dokumentation und konsistente Konformitätsprozesse.

S-SHAPER arbeitet unter strengen Qualitätssicherung & Konformität Systeme, die Materialprüfung, laufende Tests und Endinspektion in einen einzigen Workflow integrieren. Dies reduziert Risiken für US-Importeure und vereinfacht die Kommunikation mit EinzelhandelsPartnern, die Rückverfolgbarkeit fordern.

Durch die Zusammenarbeit mit einem Hersteller, der mit US-Konformitätsanforderungen bestens vertraut ist, schützen Marken ihren Ruf und vermeiden kostspielige Versandverzögerungen. Erfahren Sie mehr über S-SHAPERs Qualitätskontrollprozess und wie es fehlerfreie Lieferungen für anspruchsvolle Märkte unterstützt.

Lieferzeiten, Mindestbestellmengen und Versandlösungen für US-Bestellungen von Thong-Shapewear

Genaue Planung von Lieferzeiten ist entscheidend für Brautkalender. US-Marken verlangen oft Proben innerhalb weniger Wochen und Massenlieferungen, die mit saisonalen Starts abgestimmt sind. Flexible Mindestbestellmengen (MOQs) ermöglichen aufstrebenden Designern, Sortimente zu testen, ohne Kapital zu binden, während etablierte Marken stabile Kapazitäten für Nachbestellungen benötigen.

S-SHAPER bietet flexible MOQs und schnelle Probenfertigung, unterstützt durch intelligente Produktionsplanung und überseeische Service-Teams, die mit US-Zeitzonen synchronisiert sind. Diese Reaktionsfähigkeit hilft Marken, Prognosen anzupassen und Bestseller effizient nachzuliefern.

Die folgende Tabelle verdeutlicht typische Planungsaspekte:

| Bestellstufe | Typischer Zeitplan | Risiko bei Fehlanpassung |

|---|---|---|

| Probenahme | 2–4 Wochen | Verzögerte Anproben |

| Produktion von Massengütern | 30–45 Tage | Versäumte Startfenster |

| Versand in die USA | 7–30 Tage | Lagerengpässe oder Überbestände |

Marken können dieses Framework nutzen, um realistische Kalender zu erstellen und betrieblichen Stress zu reduzieren.

Fallstudien mit US-Braut- und Kleidermarken, die Thong-Formbekleidung einsetzen

US-Braut- und Kleidermarken, die mit S-SHAPER zusammenarbeiten, berichten häufig von verbesserten Verkaufszahlen und weniger Beschwerden zu Passformproblemen nach dem Upgrade auf maßgeschneiderte All-in-One-Thong-Formbekleidung. In einem Fall reduzierte eine DTC-Brautmarke die Rücksendungen von Formbekleidung, indem sie unsichtbare Nähte und eine verfeinerte Kompressionszone fokussierte, die mit Satin-Kleidern abgestimmt war.

Ein weiteres Etiketten für formelle Kleidung nutzte private Etikettenverpackung und mehrere Nude-Töne, um in Kaufhauskanäle vorzudringen. Die konstante Qualität bei Nachbestellungen ermöglichte es der Marke, landesweit zu skalieren, ohne in jeder Saison die Kernspezifikationen neu zu verhandeln.

Diese Ergebnisse spiegeln ein breiteres Muster wider: Wenn Formbekleidung als strategische Erweiterung des Kleides behandelt wird und nicht als nachträglicher Gedanke, gewinnen Marken sowohl das Vertrauen der Kundinnen als auch betriebliche Effizienz.

FAQ: All-in-One-Thong-Formbekleidung

Was ist die typische Mindestbestellmenge für All-in-One-Thong-Formbekleidung?

Die Mindestbestellmengen variieren je nach Stil und Anpassungsgrad, doch S-SHAPER bietet flexible Optionen, die für aufstrebende und etablierte US-Marken geeignet sind.

Kann All-in-One-Thong-Formbekleidung an spezifische Kleiderdesigns angepasst werden?

Ja, Muster, Rücken, Ausschnitte, Kompressionszonen und Farben können an Rückendekolletés, Tiefeinschnitte oder Trägerlose Kleider angepasst werden.

Wie gewährleistet S-SHAPER Fertigungspräzision?

Durch nahtloses Stricken, ±0,5 mm Schneidgenauigkeit und Echtzeit-Produktionsüberwachung, die in den QC-Prozess integriert ist.

Erfüllen die Stoffe US-Vorschriften?

Die Materialien werden so ausgewählt, dass sie den CPSIA-Anforderungen entsprechen; gängige Optionen mit OEKO-TEX-Zertifizierung sind verfügbar.

Wie lange dauert die Probenherstellung in der Regel?

Probenfertigung dauert in der Regel 2–4 Wochen, abhängig von Komplexität und Überarbeitungszyklen.

Wird Private-Label-Verpackung unterstützt?

Ja, S-SHAPER bietet vollständige Private-Label-Lösungen inklusive Etiketten, Anhänger und maßgeschneiderter Verpackung.

Zuletzt aktualisiert: 2026-01-04

Änderungsprotokoll:

- Aktualisierte US-Konformitäts- und MOQ-Details

- Verfeinerte designbezogene Aspekte für Brautmode

- Ergänztes Framework für Passformtests und Reduzierung von Rücksendungen

Nächstes Überprüfungsdatum: 2026-06-01

Nächste Überprüfungsanlässe: neue Formbekleidungssysteme, Fertigungsprozess-Updates, Änderungen bei Lieferzeiten oder MOQ, US-Regulierungsaktualisierungen

Teilen Sie diesen Beitrag:

Ähnliche Beiträge

Custom backless shapewear slip dress solutions for Spanish bridal boutiques

Custom backless shapewear slip dress solutions for Spanish bridal boutiques are no longer a niche add-on; they are becoming a core profit and service differentiator. Spanish brides increasingly choose gowns

Custom color backless shapewear slip dresses for German wedding dress retailers

German bridal retailers looking to improve gown fit, reduce alterations, and increase accessory attach rates should prioritize custom color backless shapewear slip dresses as a core part of their assortment

Custom color backless shapewear slip dresses for the French bridal market

For French bridal brands and boutiques, the fastest way to elevate customer satisfaction and increase dress conversion is to secure custom color backless shapewear slip dresses for the French bridal

Custom Color and Fabric Backless Shapewear Slip Dress Lines for Japan Boutiques

Custom color and fabric backless shapewear slip dress lines for Japan boutiques succeed when brands prioritize precision, subtle aesthetics, and stable OEM execution from the start. For Japanese boutiques, the